Armor: It does a body good

Impact-resistance trends toward smart gear

Sometimes, we have to remind ourselves we’re not Superman. We can’t shoot lasers out of our eyes, we can’t fly over buildings, and we can’t summon extraterrestrial powers to fix our everyday problems. We are only human, and often obsessed with our own shortcomings as frail vessels of soft tissue. But what really made Clark Kent so admirable to us, and dangerous to super-villains? The freak was bulletproof. In a very real sense, we want to be just as indestructible.

Personal body armor has become a multi-billion dollar industry worldwide, fueled by the meteoric rise and prevalence of ballisticly advanced bad guys. And the technology has begun to reach new levels of complexity. Engineers are finding new and ingenious ways of protecting the flesh through ceramics, woven fibers, and even biologically produced materials like spider silk.

U.S. Army Pfc. Nathan Timmons, right, helps Pfc. Chris Bursch adjust his individual body armor on Forward Operating Base Warrior, Iraq, April 1, 2007, before another mission. The soldiers are assigned to the 3rd Platoon, Alpha Company, 2nd Battalion, 35th Infantry Division, Schofield Barracks, Hawaii. (U.S. Air Force photo by Master Sgt. Andy Dunaway)

With the war in Iraq firmly in place as the world’s largest news story this decade, the most vocal call for troop withdrawal has been from those appalled at the casualties suffered by the armed forces. As of this writing, a full 1,552 of the total 3,637 troop fatalities have been attributed to improvised explosive devices (IEDs). Political considerations aside, soldiers are dying. And for some, the problem has been ineffectual body armor.

During the course of the war, the most common type of combat armor worn by U.S. troops has been the Interceptor system. Interceptor armor consists of an Outer Tactical Vest (OTV) and two Small Arms Protective Inserts (SAPIs). The OTV is made of a Kevlar aramid, a bullet-resistant webbing sandwiched between layers of plastic film, which acts like a microscopic and powerful soccer net, spreading out the energy of a projectile to dissipate across a larger area. The SAPIs are made of ultra-hard boron carbide ceramic plates.

Of George W. Bush’s recent $87 billion package for ongoing military operations, $300 million has been earmarked for troop body armor. And with a complete system cost of about $1,585, personal protection doesn’t come cheap.

However, on May 4, 2005, the U.S. Marine Corp recalled 5,277 Interceptor vests when reports began to surface that they were unable to stop 9-mm bullets. By November, the Marine Corp had pulled 10,342 vests from the front lines.

To offset the frighteningly inadequate government issued vests, troops began to privately purchase their own body armor, namely the Dragon Scale system from Pinnacle. Dragon Scale is characterized by its small circular discs that overlap like reptile scales creating a flexible yet impenetrable vest, allowing greater range of motion with advanced protection. Under pressure from Congress, the Department of Defense even went so far as to grant a one-time $1,000 reimbursement to soldiers that had purchased civilian gear.

But pressures from the defense contractor lobby forced military leaders to change their tune, and soldiers were eventually told to leave their Dragon Scale behind. Indeed, some soldiers were even informed that if they were wearing the Pinnacle armor and were killed in combat, their beneficiaries would not be eligible for their death benefits under their $400,000 SGLI life insurance policies.

So with the current Interceptor in question, on May10, 2006, the Army announced an open competition for the design of a new generation of body armor to replace the current models. The result was a $33 million indefinite delivery, indefinite quantity (ID/IQ), contract with American-based ceramics maker ArmorWorks.

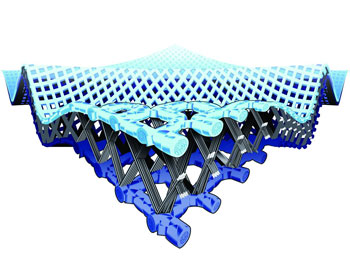

Dow Corning’s Active Protection fabric is treated with a silicone coating that remains flexible until struck with high-impact force, when it then becomes rigid.

While ArmorWorks’ new Improved Outer Tactical Vest (IOTV) is still based on synthesized ceramics and Kevlar, there are a number of products and technologies emerging that have the potential of revolutionizing the body armor industry.

Researcher Okenwa Okoli of the Florida A&M - Florida State University College of Engineering believes he and his team are close to a ground-breaking armor technology at FSU’s High-Performance Materials Institute (HPMI).

Okoli has been working with Nanotubes, a carbon-based material, much smaller than human hair, but with astonishing strength. Nanotubes are derived from the unique carbon molecule, buckminsterfullerene, which is simultaneously extremely strong and lightweight. Chemistry professor Harold Kroto discovered the molecule, nicknamed “buckyballs," and shared the Nobel Prize for Chemistry with his two colleagues, Richard E. Smalley and Robert F. Curl Jr., in 1996.

The armor is developed from a composite manufacturing process to create lightweight plates using nanotubes to protect soldier’s arms, legs, and head. Okoli hopes that these lightweight carbon-based composite materials will replace heavier metals, and he is currently working with the U.S. Air Force to develop specific armor for parajumpers.

New Jersey-based Honeywell is also on the forefront of advanced materials. Their new Spectra Shield II fiber is 15 times stronger than steel, yet light enough to float. Spectra fiber was developed specifically for use in armor, and is made from an ultra-high-molecular-weight polyethylene using a patented gel-spinning process. The fiber is known to have high resistance to chemicals, water, and ultraviolet light. Honeywell also claims it has superior vibration damping, flex fatigue and fiber-friction, and has up to 60% greater specific strength than traditional aramid fiber.

The Spectra Shield products are manufactured by bonding parallel strands of fiber in place with an advanced resin system to form bullet-resistant vests, breastplates, and helmets. Like all Honeywell fiber-based materials, the Spectra fiber is also transparent to radar.

The Nirvana Protection Vest, from Mammut, using Dow Corning’s Active Protection System, was unveiled at the International Trade Show for Sports Equipment and Fashion this February in Munich, Germany.

Perhaps the most novel approach to personal body protection comes from outside the military applications arena. Dow Corning’s Active Protection System looks to protect athletes and sports enthusiasts from the less dangerous impacts of physical activity. Using its patented “smart” technical textile materials, Dow Corning has sold its technology to sports apparel companies like the Mammut (Switzerland) and Rukka (Finland).

Treated with a specially formulated silicone coating, the Active Protection System fabric remains soft and flexible under normal conditions. When struck by high-impact force, however, the material instantly becomes rigid to help protect the wearer against injury. Once the impact is over, it immediately becomes flexible again.

While the fabric won’t be stopping bullets in Baghdad any time soon, potential applications are virtually unlimited. Down Corning views the system as marketable in protective sports and work apparel, industrial and geo fabrics, protective medical devices, architecture and construction, and even security and civil defense.

“The Active Protection system marks a huge leap forward in personal impact protection,” says Liz Mallen, Ph.D., Dow Corning’s business development manager for impact protection. “We believe this is a true ‘fabric of the future’ that can substantially improve the quality of life for people all over the world in many different ways.”

Now if only they can work on that seeing through walls thing.

Want more information? Click below.

Dow Corning

Want more information? Click below.

Honeywell

Want more information? Click below.

ArmorWorks

© Nelson Publishing, Inc. All Rights Reserved