Designfax – Technology for OEM Design Engineers was launched as an exclusive eMagazine in October 2005 following 25 successful years in print. Subscribers to the weekly publication (48 issues a year) are high-level OEM product design engineers and engineering managers who operate in a broad range of manufacturing industries, including automotive, aerospace, appliances, medical equipment, transportation, computer process controls, industrial equipment, and more. Primary content focuses on the latest exciting applications and products for Electrical/Electronic, Mechanical, Motion Control, Fluid Power, and Materials engineering, including articles on powerful software programs that serve as a primary engineering tool. Take a look at what Designfax offers and then subscribe.

| January 13, 2026 | Volume 22 Issue 02 |

| | Feature articles |

| 2026 Corvette ZR1X: Next-gen American hypercar

The 2026 Corvette ZR1X is an all-day comfortable tourer, a straight-line rocket, and a racetrack weapon, all in one. With a total of 1,250 hp available, a 5.5L V8, electrified all-wheel drive, and a 0- to 60-mph time of under 2 sec, ZR1X is a true, next-gen American hypercar and the most advanced Corvette ever.

Read the full article. |

|

| Aluminum turned transparent using tiny droplets

Researchers in the Philippines and Japan have devised an easier way to make very thin sheets of aluminum transparent. The see-through aluminum oxide is incredibly hard and resistant to scratches, making it a great candidate for protective coatings on electronics, optical sensors, and solar panels.

Read the full article. |

| Ferrari Testarossa: The 1980s icon is back!

The ultimate '80s supercar has been reborn. Ferrari's 849 Testarossa is a hybrid plug-in super sports berlinetta equipped with three electric motors alongside the mid-rear twin-turbo V8, delivering a total of 1,035 hp -- 50 more than the car it replaces. It looks sweet too.

Read the full article. |

| First look: Advanced autonomous naval attack vessel

Want to know what's next-level and next-generation in the world of naval attack vessels? Take a look at the AIRCAT Bengal MC from U.S. defense company Eureka Naval Craft -- a fast and efficient autonomous surface effect ship that can carry a 40-ton payload, including a full suite of sensors and weapons.

Read the full article. |

| Top Product: Print 316L stainless steel on Markforged printers

316L Stainless Steel is now available for use with Markforged FX10 printers, allowing users to manufacture high-strength, accurate parts for demanding applications such as food and beverage processing, automotive, chemical and petrochemical processing, medical devices, and marine environments. This filament is safe and easy to handle. It makes machinable and polishable parts that have excellent corrosion resistance.

Learn more. |

| Top Product: Smalley's new Nestawave™ Spring

Introducing Nestawave™ -- the spring that redefines compact power. As the latest innovation in Smalley's wave spring technology, Nestawave combines the deflection of a Crest-to-Crest® wave spring with the force of a nested spring. It delivers high load capacity and significant travel in tight spaces. Ideal for replacing stacks of Belleville washers, it performs in valves, bearing preloads, compressors, and more. Try the Smalley advantage and request your samples today.

Learn more and get samples of this NEW Smalley product. |

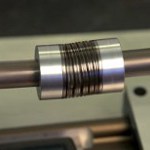

| Top Product: Accommodate large misalignments, get hidden benefits

C-Flex Couplings combine the best qualities of disc, beam, and bellows couplings in a unique and economical design. Made to couple two rotating shafts together, these couplings can accommodate large misalignments while transmitting high torque loads with zero backlash. Benefits include lower energy usage and less-frequent bearing failure. These couplings require no maintenance and provide years of trouble-free life. Flexible Pivot Bearings and Super Plastic Torsional Damping Couplings also available.

Learn more and get all the specs and options. |

| Top Resources: ABCs of gears and more

KHK USA takes you on a journey through the history and applications of gears in two information-packed, no-cost volumes called "The ABCs of Gears." Part A is aimed at beginners, while part B moves on to intermediate fare, such as types of gears and tooth forms, heat treatment, surface treatment, production methods, etc. Another mid-level text called "Introduction to Gears" and an in-depth "Gear Technical Reference" are also available. No registration required.

Check out these valuable KHK resources. |

| Top Product: Where do you get drone parts?

Based in Buffalo, NY, Allient is furthering its robust technology foundation to deliver advanced motion and power solutions for unmanned aerial systems, starting with COTS propulsion motors and extending to electronic speed controllers, gimbals, propellers, mission-ready kits, and power/electronic solutions. Across all product categories, the company manufactures more than 5 million motors annually.

Read the full article. |

| | Most popular last issue |

| Aero History: WWII Superfortress bomber engine struggles

In July 1944, a B-29 Superfortress aircraft conducted a series of flight tests at the NACA Aircraft Engine Research Laboratory (now NASA Glenn) in Cleveland, OH. The tests were part of a national effort to get the new bomber into combat as the Allies sought to turn the tide in the Pacific theater of World War II.

Read the full article. |

| How to pin a shaft and hub assembly

One of the primary benefits of using a coiled spring pin to affix a hub or gear to a shaft is the coiled pin's ability to prevent hole damage. Another is the coiled pin absorbs wider hole tolerances than any other press-fit pin. This translates to lower total manufacturing costs of the assembly. However, there are a few design guidelines that must be adhered to in order to achieve the maximum strength of the pinned system and prevent damage to the assembly.

Read this informative SPIROL article. |

|

| | Videos+: Technologies and inspiration in action | Guy builds omni-directional ball-wheeled bike

We featured YouTube maker James Bruton and his funky, self-built Mecanum wheel screw bike back in September 2024. Since then, Bruton has been busy; this time around he has designed and created an equally wacky omni-directional ball-wheeled bike. He says he used 3D printing for much of the build and five ODrive brushless motors to keep the balls spinning. Really fun to see him work it all out. Riding the bike brings a whole new meaning to drifting. [Credit: Screenshot courtesy of James Bruton YouTube channel]

View the video. |

|

See how Craftsman tool boxes are made

YouTuber ChrisFix takes viewers on a step-by-step tour of how Craftsman makes one its best-selling, multi-drawer tool boxes at the company's giant factory in Sedalia, MO. Who doesn't like to see all the metal cutting and forming it takes to make something so long lasting and useful? [Credit: Image courtesy of Craftsman]

View the ChrisFix video. |

|

|

|

If you choose not to receive any more issues of Designfax, please follow this link

|