| December 19, 2023 | Volume 19 Issue 47 |

| Merry Christmas and Happy Holidays from Designfax!

2023 was another year overflowing with challenges for us all, but we made it! Thanks to all our readers, sponsors, writers, and article contributors. We wish you a healthy and happy holiday season!

Don't forget to pass along your issue of Designfax to an engineering colleague.

Please check out our sponsors every week. They make our publication possible. If you're looking to advertise, we can help with that too.

Go to the Designfax advertise page. |

| | Feature articles |

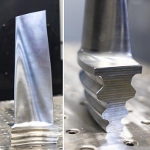

| 3D printing's cutting edge: Metal steam turbine blade

Researchers at Oak Ridge National Lab have become the first to 3D print large, rotating steam turbine blades for generating energy in power plants. Led by partner Siemens Technology, the project demonstrates that wire arc additive manufacturing is viable for the scalable production of these sizable, critical components.

Read the full article. |

|

| Christmas around the Moon: Apollo 8

Christmas Eve, 1968. As one of the most turbulent, tragic years in American history drew to a close, millions around the world were watching and listening as the Apollo 8 astronauts -- Frank Borman, Jim Lovell, and Bill Anders -- became the first humans to orbit another world.

Read the full article. |

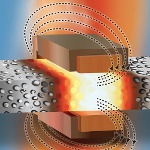

| Researchers weld metal foam without melting its bubbles

Researchers at North Carolina State University have identified a welding technique that can be used to join composite metal foam (CMF) components together without impairing the properties that make CMF desirable: lightweight, strong, and effective at insulating against high temps. CMFs hold promise for a wide array of applications from aircraft wings to vehicle armor.

Read the full article. |

| First-ever Toyota Crown Signia SUV: Pushing that luxe life

Toyota is reaching for new heights in luxury with the introduction of the 2025 Crown Signia mid-size SUV -- a significant upgrade to the Toyota Venza it replaces. Exclusively equipped with the Toyota Hybrid Electric Vehicle powertrain with On-Demand AWD standard, the Crown Signia will be available in XLE and Limited grades and powered by a 2.5-L DOHC four-cylinder engine with two electric motor generators.

Read the full article. |

| 6 considerations for selecting a ball valve

Ball valves are the ideal valve of choice for liquid and gas conveyance lines ranging from diesel fuel to compressed air. Although these valves may seem simple, there's a lot more to them. Parker Hannifin offers valuable advice on body materials, configuration, seals, venting, and more in this informative post.

Read the Parker blog. |

| AI monitors conveyor tech at BMW assembly plant

Preventing unplanned stoppages before they can occur is the aim of the smart analysis system being used in assembly at BMW's Group Plant in Regensburg, Germany. The AI-supported system monitors conveyor technology during assembly, identifying potential faults early and avoiding more than 500 minutes of vehicle assembly disruption every year.

Read the full article. |

| FAULHABER IEP3 incremental encoder: Impressive accuracy through latest chip tech

With a diameter of just 8 mm, FAULHABER's new IEP3 incremental encoder is lightweight and compact yet still offers a resolution up to 10,000 lines per revolution -- made possible by the latest chip technology with high interpolation. The chip ensures a high positional accuracy of 0.3° m as well as high repeatability thanks to accuracy compensation. Application areas include telescopes, microscopes, lasers, and cameras; semiconductor production; robotics; and prosthetics.

Learn more. |

| New EXAIR catalog: Solutions for manufacturing problems

EXAIR's new Catalog 35 is a full-color technical guide offering innovative solutions to common industrial conveying, cooling, cleaning, blowoff, drying, coating, and static electricity problems. The expanded Catalog 35 features new products, guides, research, certifications, and many other helpful tools to assist customers in getting the most out of their manufacturing processes.

Get your EXAIR Catalog 35. |

| Orbex offers two fiber optic rotary joint solutions

Orbex Group announces its 700 Series of fiber optic rotary joint (FORJ) assemblies, supporting either single or multi-mode operation ideal for high-speed digital transmission over long distances. Wavelengths available are 1,310 or 1,550 nm. Applications include marine cable reels, wind turbines, robotics, and high-def video transmission. Both options feature an outer diameter of 7 mm for installation in tight spaces. Construction includes a stainless steel housing.

Learn more. |

| Intelligent compact drives with extended fieldbus options

The intelligent PD6 compact drives from Nanotec are now available with Profinet and EtherNet/IP. They combine motor, controller, and encoder in a space-saving package. With its 80-mm flange and a rated power of 942 W, the PD6-EB is the most powerful brushless DC motor of this product family. The stepper motor version has an 86-mm flange (NEMA 34) and a holding torque up to 10 Nm. Features include acceleration feed forward and jerk-limited ramps. Reduced installation time and wiring make the PD6 series a highly profitable choice for machine tools, packaging machines, or conveyor belts.

Learn more. |

| | Most popular last issue |

| How Lexus fixed Tesla's bad idea: Steer-by-wire yoke

Are you ready for steer-by-wire technology, where there is no mechanical connection between the steering wheel and the front wheels of your car? Engineering Explained's Jason Fenske runs through the advantages and disadvantages (both from engineering and user standpoints) of this system, and why Lexus' system (available on upcoming Lexus RZ 450e models) with self-adjusting variable steering ratio is a winner over Tesla's attempts to implement the technology.

View the Engineering Explained video. |

|

| | Videos+: Technologies and inspiration in action | Custom hot rod parts: Digital sheet metal forming machine

Learn how SaltWorks Fab in Sarasota, FL, is using Desktop Metal's Figur G15 Digital Sheet Forming (DSF) machine to create ultra-cool custom car parts in under an hour -- with no need for specialized tooling. The Figur technology uses a software-driven ceramic toolhead on a gantry to shape standard sheet metal into parts with up to 2,000 lb of force. The machine handles a maximum sheet size of 1,600 x 1,200 mm (63.0 x 47.2 in.) and delivers parts with a draw depth up to 400 mm (16 in.) in Z without custom forming tools, molds, dies, or presses.

Learn how SaltWorks Fab in Sarasota, FL, is using Desktop Metal's Figur G15 Digital Sheet Forming (DSF) machine to create ultra-cool custom car parts in under an hour -- with no need for specialized tooling. The Figur technology uses a software-driven ceramic toolhead on a gantry to shape standard sheet metal into parts with up to 2,000 lb of force. The machine handles a maximum sheet size of 1,600 x 1,200 mm (63.0 x 47.2 in.) and delivers parts with a draw depth up to 400 mm (16 in.) in Z without custom forming tools, molds, dies, or presses.

View the video.

Learn more about the Figur G15 machine tech. |

|

|