| March 26, 2024 | Volume 20 Issue 12 |

|

| Need inserts? We make it E-Z.

Founded in 1956, E-Z LOK allows users to repair damaged or worn-out threads without the need for special taps or installation tools. Our line of threaded locking inserts is used in metal, plastic, wood, composite and additive industries. Extensive inventories are maintained in four warehouses across the US, and all products are sold through industrial distributors. One source for all your needs!

Learn more

or contact Kyle Lindsly-Roach for free samples at 310.323.5613 x221. |

| All-new 2025 Infiniti QX80: Wow, what a ride

If you are in the market for a three-row, ultra-premium ride, look no further. The all-new Infiniti QX80 has all your needs covered and then some. From its solid 450-hp twin-turbo engine to its electronic air suspension, world-first camera views, and every-seat-a-first-class-experience interior, this flagship SUV will get you to your destination safely in high spirits and high style.

Read the full article. |

| Seifert thermoelectric coolers from AutomationDirect

AutomationDirect has added new high-quality and efficient stainless steel Seifert 340 BTU/H thermoelectric coolers with 120-V and 230-V power options. Thermoelectric coolers from Seifert use the Peltier Effect to create a temperature difference between the internal and ambient heat sinks, making internal air cooler while dissipating heat into the external environment. Fans assist the convective heat transfer from the heat sinks, which are optimized for maximum flow.

Learn more. |

| Top Tech Tip:

2D, 3D, or 2.5D? Choosing a vision system for your automation project

If you are looking at machine vision systems for automation, you will need to decide whether to invest in a 2D, 3D, or 2.5D camera system. That choice will have a major impact on the deployment's cost, complexity, capabilities, and functionality. OnRobot's Kristian Hulgard, General Manager - Americas, explains the differences, benefits, and shortcomings of each system type.

Read the full article. |

| Break the mold with custom injection molding by Rogan

With 90 years of industry experience, Rogan Corporation possesses the expertise to deliver custom injection molding solutions that set businesses apart. As a low-cost, high-volume solution, injection molding is the most widely used plastics manufacturing process. Rogan processes include single-shot, two-shot, overmolding, and assembly. Elevate your parts with secondary operations: drilling and tapping, hot stamping, special finishes, punch press, gluing, painting, and more.

Learn more. |

| EMI shielding honeycomb air vent panel design

Learn from the engineering experts at Parker how honeycomb air vent panels are used to help cool electronics with airflow while maintaining electromagnetic interference (EMI) shielding. Topics include: design features, cell size and thickness, platings and coatings, and a stacked design called OMNI CELL construction. These vents can be incorporated into enclosures where EMI radiation and susceptibility is a concern or where heat dissipation is necessary. Lots of good info.

Read the Parker blog. |

| World's first current-carrying fastening technology

PEM® eConnect™ current-carrying pins from PennEngineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

Learn more about eConnect pins. |

| New line of electric servomotor brakes

Nexen's Evolve Electric Servomotor Brake line is spring engaged and electrically released, and engineered with a double-sided friction interface for increased torque capacity. The double-row, angular contact bearing delivers overhung load capacity and rigidity, allowing machine builders and OEMs to design a more robust machine. The brakes, featuring zero backlash for precision holding and low inertia, can easily be configured to match the motor and gearhead mating interfaces.

Learn more. |

| New interactive digital catalog from EXAIR

EXAIR's latest catalog offers readers an incredible source of innovative solutions for common industrial problems like conveying, cooling, cleaning, blowoff, drying, coating, and static buildup. This fully digital and interactive version of Catalog 35 is designed for easy browsing and added accessibility. Customers can view, download, print, and save either the full catalog or specific pages and sections. EXAIR products are designed to conserve compressed air and increase personnel safety in the process. Loaded with useful information.

Check out EXAIR's online catalog. |

| | Most popular last issue |

| All-new Dodge Charger: All-electric and V-6 options

The all-new Dodge Charger is a big deal, not only because it will come as both EV (Daytona) and gasoline (SIXPACK) models with two or four doors, but because this is literally a super-husky ride: over 17 ft long and nearly 7 ft wide, and weighing over 5,800 lb as an all-electric option. It will retain its title as the world's quickest and most powerful muscle car, though, with a 670-hp option that will do 0 to 60 in 3.3 sec.

Read the full article. |

| Pinball design: Making the Godzilla machine -- Stern Pinball

Is being a pinball designer at the top of your dream jobs list? Watch as the engineers and game designers from Stern Pinball chronicle the development of their wildly inventive Godzilla pinball machine -- from concept to handmade prototype mechanisms and a whole lot more. An informative inside look at how all the fun gets put together, including a multi-level moving tower that shakes up traditional game play. [Image credit: Stern Pinball video screenshot]

View the video. |

|

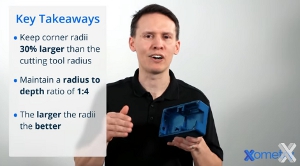

| | Videos+: Technologies and inspiration in action | 5 cost-saving design tips for CNC machining

Make sure your parts meet expectations the first time around. Xometry's director of application engineering, Greg Paulsen, presents five expert tips for cutting costs when designing custom CNC machined parts. This video covers corners and radii, designing for deep pockets, thread depths, thin walls, and more. Always excellent info from Paulsen at Xometry.

Make sure your parts meet expectations the first time around. Xometry's director of application engineering, Greg Paulsen, presents five expert tips for cutting costs when designing custom CNC machined parts. This video covers corners and radii, designing for deep pockets, thread depths, thin walls, and more. Always excellent info from Paulsen at Xometry.

View the video. |

|

|