| April 22, 2014 | Volume 10 Issue 16 |

|

| Molded Nylon Special Standard Round Spacers

Micro Plastics announces a new product line of Special Standard Round Spacers. The new line of molded nylon round spacers includes over 250 sizes, with diameters of 1/8" through 1 1/2" and lengths from 1/8" to 2 3/4". These tough, resilient spacers can be used in a variety of assemblies. Useful in electronic and electrical applications, they may also be used as bushings, bearings, rollers, gliders, and bumpers. They are resistant to vibration, abrasion, and corrosion; are electrically insulating; and have a high strength-to-weight ratio.

Click here to learn more. |

| | Feature articles |

| NASA researchers team up to tackle sonic boom

Since the Concorde's final landing at London's Heathrow Airport nearly a decade ago, commercial supersonic air travel has been as elusive as a piece of lost luggage. However, this hasn't stopped NASA from continuing the quest to develop solutions that will help get supersonic passenger travel off the ground once more.

Read the full article. |

|

| Mike Likes:

Monitor engine oil condition in all kinds of machinery

Make interval oil changes a thing of the past using the new STAUFF Oil Quality Sensor (OQS). This unit monitors oil condition and can be permanently mounted within any lubrication system on nearly any type of machine, including: diesel and gas engines, compressors, industrial gear reducers, wind turbines, generator sets, hydraulic systems, and more. OQS measures the energy loss component of oil permittivity. All contaminants such as metallic particles, soot, water, oxidization, glycol, and particularly burnt fuel dilution increase this measured value. Data can be displayed on your existing system or on the STAUFF Oil Quality Display (OQD). This is an excellent way to build extra, billable value into your designs.

Click here to learn more. |

| Smalley's new website makes 'invisible' parts easy to find

What do the Mars Lander and high-performance athletic shoes have in common? You could stare at them all day and never come up with the right answer. That's because what they share isn't visible to the naked eye. Each contains an internal component from the Smalley Steel Ring Company, the world leader in the manufacturing and development of Spirolox® Retaining Rings, Constant Section Rings, and Wave Springs. While invisibility is a huge advantage for some technology, when it comes to the Internet, engineering design professionals and other consumers need to be able to sight what they're after quickly and easily. That's why Smalley has just launched a full redesign of their website, www.smalley.com, which features improved navigation, new functionality, and updated content that reflects the cutting-edge solutions the company offers.

Check out the new Smalley website. |

| Self-clinching standoffs for ultra-thin stainless steel assemblies

New PEM Type TSO4 self-clinching stainless steel standoffs from PennEngineering provide ideal fastener solutions for stacking or spacing components to (or from) ultra-thin stainless steel panels. These specially hardened stainless fasteners install reliably and permanently into stainless steel sheets as thin as .025 in./0.63 mm with only a single mating screw required for final component attachment. They ultimately enable lighter designs by minimizing hardware count and offer the added benefit of excellent corrosion resistance for an assembly.

Click here to learn more. |

| Cageless and high-peak torque motors

When an application does not require a motor to be in a caged structure, the TML and TMM cageless and high-peak torque motors from ETEL are lighter, lower-cost alternatives to ETEL's better known TMB model, yet still provide a direct-drive technology option. These motors can provide an ideal solution for applications that have less-demanding continuous-torque requirements. They are able to provide the same peak torque as the famous TMB range with up to 5,000 Nm and reach speeds to 2,100 rpm. The TML/TMM both come in multiple standard sizes that vary in diameter, length, and power, and each model offers different types of coil winding providing more performance variations.

Click here to learn more. |

| | Most popular last issue |

| Army tests improved coatings for howitzer spindles

Efforts by U.S. Army engineers at Aberdeen Proving Ground, MD, to implement an improved coating for howitzer breech spindles aim to provide several benefits: easing the logistical burden on Soldiers, reducing hazardous waste, and saving millions of dollars. The engineers evaluated 12 material formulations in small samples and then down-selected to three based on performance and cost.

Read the full article. |

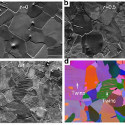

| A new twist produces better steel

In steel making, two desirable qualities -- strength and ductility -- tend to be at odds: Stronger steel is less ductile, and more ductile steel is not as strong. Engineers at Brown University, three Chinese universities, and the Chinese Academy of Sciences have shown that when cylinders of steel are twisted, their strength is improved without sacrificing ductility.

Read the full article. |

|

| | Videos+: Technologies and inspiration in action | Fly using Rockwell Collins head-up display

Rockwell Collins' Senior Manager of Head-up Guidance Systems (HGS) Flight Operations, Dean Schwab, demonstrates how easy and intuitive it is to operate HGS. The demonstration was completed in the company's Portland, OR-based simulator. The simulated approach was into the mountainous region of Innsbruck, Austria, demonstrating how synthetic vision greatly enhances situational awareness. Rockwell Collins is the only company that has certified synthetic vision on a head-up display. The company has a newer video about this technology, featuring the EVS-3000 enhanced vision sensor along with the capability to display both synthetic vision and enhanced vision in a head-up display, but this video does the best job of explaining using the technology. Remember, keep the little circle inside the slightly bigger circle ...

View the video. |

|

High-altitude wind turbine aims to break world record in Alaska

Altaeros Energies, a wind energy company formed out of MIT, says that its demonstration project south of Fairbanks, Alaska, is set to break the world record for the highest wind turbine ever deployed. The $1.3 million, 18-month project will send the Altaeros BAT to a height 1,000 ft above ground -- over 275 ft taller than the current record-holding ground-based wind turbine. The BAT (Buoyant Airborne Turbine) project, partially financed by the Alaska Energy Authority's Emerging Energy Technology Fund, will also be the first long-term demonstration of an airborne wind turbine. The BAT uses a helium-filled, inflatable shell to lift to high altitudes where winds are stronger and more consistent than those reached by traditional tower-mounted turbines. These high-altitude winds help generate twice the power of ground-based systems, according to Altaeros engineers.

View the video. |

|

|

|