| June 17, 2014 | Volume 10 Issue 23 |

|

| Design Tips: 12 Essentials for Moldability

Ten years ago, we began publishing Protomold Design Tips to help product developers create better injection-molded plastic parts. We've covered materials, texture, draft, sink and many other design considerations. More than 100 tips later, we remain steadfast in our effort to continue informing designers and engineers in all areas of injection-molded part design. As a resource, we've gathered some of our most useful manufacturing advice from the past decade in a collection of essential tips.

Get your Protomold Design Tips today. |

| Piezo motor technology: Questions answered

There's a new kind of piezo motor in town, and it's got legs. The Piezo LEGS® rotational motor is a direct-friction drive that provides precise motion without any mechanical play or backlash. There are no gears or transmission, so changing the direction of the motion will introduce no error. The simple Piezo LEGS® motor is also extremely stiff. Find out the answers to frequently asked questions about this exciting new motor technology.

Read the full article. |

| Basics of motion control:

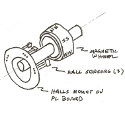

How feedback encoder devices operate

Feedback is used in closed-loop systems in applications all over the world to control speed and/or position, and it has an important role in keeping equipment operating smoothly and accurately. Feedback is available in a variety of devices as well as models. It is important to understand how feedback operates, so the best benefits can be used in the application. This article reviews: open-loop vs. closed-loop applications, tachometers, Hall sensors, incremental encoders, absolute encoders, and resolvers.

Read the full article. |

| New family of USB power delivery controllers

Microchip Technology has created a new family of USB power delivery (UPD) controllers: the UPD100X with an industry-standard power delivery and battery charging protocol. A single USB cable can be used for data and simultaneously deliver up to 100W of power from a single standard USB port, which is 40 times the power compared to USB 2.0. Evaluation kit also available.

Click here to learn more. |

| Step-by-step guide to automate welding

Are you considering automating of your welding process? Robotiq has designed a take-away guide and evaluation grid that will help you consider important aspects of the robotic welding process. This guide will also help you highlight the different points to evaluate at each stage and calculate your return on investment.

Click here to learn more. |

| Rolling bearings for industrial gearboxes

NKE Austria offers rolling bearings for industrial gearboxes that meet the efficiency and reliability requirements of a wide range of sectors, such as general machinery, mining, material handling systems, and heavy machinery. NKE manufactures over 3,000 different variants of bearings suitable for high radial loads and moderate to high speeds. Made from pure rolling bearing steel, they have an exceptional lifespan, while the raceways' high surface quality reduces the operating temperature and wear. The inner and outer rings of the cylindrical roller bearings can be fitted separately, simplifying installation. They can be ordered with short lead times through the main U.S. distributor Ritbearing.

Click here to learn more. |

| Fast and svelte 6-axis robots

The new Epson C4 and C4L compact 6-axis robots feature faster speeds and more payload capability than the C3 models, while keeping the popular SlimLine design. These are some of the fastest compact 6-axis arms available in the industry. The slim body and compact wrist allow for the units to easily reach into confined and restricted work spaces from many angles with a smooth motion. The tight integration of powerful motors and amplifiers along with ultra-high-resolution feedback and superior controls provide unmatched motion performance, including higher acceleration and deceleration rates as well as advanced linear interpolated motion. They are ideal for small parts assembly, dispensing, lab automation, machine tending, material handling, packaging, and more.

Click here to learn more. |

| | Videos+: Technologies and inspiration in action | How Loctite threadlockers and retaining compounds help Polaris snowmobiles go extreme

Go inside the Polaris manufacturing facility to hear company engineers explain why they use different kinds of Loctite anaerobic threadlockers and retaining compounds to enhance the durability of their snowmobiles. Polaris sleds are the choice of competitive snocross racers and X Games athletes because they are built to endure the punishment of full-out driving maneuvers, high loads, and crashes.

View the video. |

|

|

|