| July 15, 2014 | Volume 10 Issue 27 |

|

| Design Tips: 12 Essentials for Moldability

Ten years ago, we began publishing Protomold Design Tips to help product developers create better injection-molded plastic parts. We've covered materials, texture, draft, sink and many other design considerations. More than 100 tips later, we remain steadfast in our effort to continue informing designers and engineers in all areas of injection-molded part design. As a resource, we've gathered some of our most useful manufacturing advice from the past decade in a collection of essential tips.

Get your Protomold Design Tips today. |

| | Feature articles |

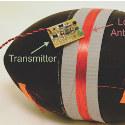

| Engineers try to tackle how to track a football in 3D space

Referees may soon have a new way of determining whether a football team has scored a touchdown or gotten a first down. Researchers from North Carolina State University and Carnegie Mellon University, in collaboration with Disney Research, have developed a system that can track a football in three-dimensional space using low-frequency magnetic fields.

Read the full article. |

|

| That's possible?! What you didn't know about silicone adhesives

Versatile and reliable, silicone adhesives are prime for use in the engineering of appliances, electronics, outdoor power equipment, aerospace components, and myriad other products. Shirley Monte of FLEXcon lays out some reasons that silicone adhesives are considered a better alternative to traditional joining methods, including screws, nuts, bolts, rivets, welds, and other mechanical fasteners.

Read the full article. |

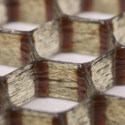

| 3D-printed honeycombs challenge material performance of balsa wood

Harvard researchers are giving balsa wood a run for its money. The low-tech but expensive material is used as a core material in giant wind turbine blades, among many other applications. Using a cocktail of fiber-reinforced epoxy-based thermosetting resins and 3D extrusion printing techniques, materials scientists at Harvard have developed cellular composite materials of unprecedented light weight and stiffness.

Read the full article. |

| Mike Likes:

Low-profile retaining rings

Smalley Hoopster® Rings fit into shallower grooves than regular snap rings or retaining rings. Where retaining rings once were not an option because of groove depth, the low profile, precision circularity & small radial size allow the Hoopster to be an unobtrusive component in the assembly, ideal for thin wall tubes. Hoopster Retaining Rings are easily installed without special tools. Standard sizes are stocked from 3/8" to 3" and offered in carbon and 302 stainless steel.

Click here to learn more. |

| Engineer's Toolbox:

Technology that gets under your skin

For some years now, tattoos have gained mainstream acceptance. Women are also now enhancing their beauty with "permanent make-up," whereby eyeliner or lip contours are permanently applied. What does this have to do technology? In the handy machines used for tattoos and permanent make-up, there are FAULHABER coreless DC motors from MICROMO.

Read the full article. |

| Great references:

Basics of Hydraulic/Pneumatic Cylinders design guide

After a reader asked me last week about some hydraulic cylinder basics, I was reminded of an excellent resource from Milwaukee Cylinder that interested engineers should download for themselves. Milwaukee Cylinder's Design Engineer's Guide does a fantastic job of covering basic cylinder operating principles, standard NFPA mountings, cylinder sizing, air and hydraulic cylinder force and speed, and much, much more. This is a no-cost, no-sign-up invaluable reference. Design Engineer's Guide is the 11th item on the page. Other good materials available.

Click here to go to the Guide page. |

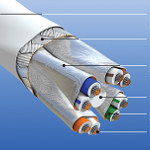

| Ethernet cables for aerospace

W. L. Gore & Associates, Inc. (Gore) introduces GORE Ethernet Cables to meet the military and civil aerospace markets' emerging need for higher-data-rate cables in a lightweight, flexible, and routable package. Featuring the unique cable jacket material found in GORE 1394b FireWire Cables, GORE Ethernet Cables provide the ideal combination of high speed and light weight necessary for a wide range of aerospace applications. This CAT-6A cable supports TIA-568 applications up to 10 gigabits while increasing signal density with reduced cable diameter.

Click here to learn more. |

| Structural adhesives for vehicle assembly

SCIGRIP provides transportation design engineers with a series of structural adhesives specifically formulated to provide tough, durable bonds for a wide range of metal, thermoset composites, and thermoplastic substrates. These low-VOC methacrylate adhesives bond metal, composites, and plastics to enable quicker, more economical, and less labor-intensive assembly operations than mechanical joining methods or welding techniques. SCIGRIP adhesives are available in several product series with a variety of curing times, from products that set in as little as 4 to 6 min. for relatively small applications, or as long as 15 to 40 min. for more complicated assemblies requiring precise positioning.

Click here to learn more. |

| New ironless linear motor

The UXX is the most powerful standard ironless motor Tecnotion offers. It is ideal for heavy-duty industrial applications that demand ultra-precision and maximum-force output. With no cogging and zero attraction force between the coil and the magnets, it is ideal in flat-panel and semiconductor applications, and many others.

Click here to learn more. |

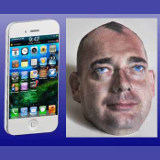

| | Videos+: Technologies and inspiration in action | Neat and novel: Paper models come to 3D printing

At the Consumer Electronics Show (CES) 2014 earlier this year, 3D-printing entrepreneur Dr. Conor MacCormack, Co-founder & CEO of Ireland-based Mcor Technologies, showed off the company's clever paper-based 3D printing technology. That's right, the 3D phone and head models at right are made of paper! How does that work? 1. Each layer of a design is printed on a sheet of paper using high-saturation inks. 2. The stack of paper is put into the "printer," where each piece is carefully edge-glued with special adhesives and cut. 3. The model stack grows. 4. Pop your finished color model out of the precision-glued and cut stack. MacCormack says that paper-based 3D models are serious prototyping contenders, because the model cost is so low: often around 10 bucks or less a pop. Neat and novel. (Video by ElectricTV)

View the video. |

|

|

|