| October 28, 2014 | Volume 10 Issue 40 |

|

| Molded Nylon Special Standard Round Spacers

Micro Plastics announces a new product line of Special Standard Round Spacers. The new line of molded nylon round spacers includes over 250 sizes, with diameters of 1/8" through 1 1/2" and lengths from 1/8" to 2 3/4". These tough, resilient spacers can be used in a variety of assemblies. Useful in electronic and electrical applications, they may also be used as bushings, bearings, rollers, gliders, and bumpers. They are resistant to vibration, abrasion, and corrosion; are electrically insulating; and have a high strength-to-weight ratio.

Click here to learn more. |

| Great alternatives to riveting or spot welding

PEM SpotFast self-clinching fasteners from PennEngineering are ideal solutions to attach two aluminum or steel sheets that are too thin to weld, fasten sheets of unequal thicknesses, join dissimilar metals, attach ultra-thin metal sections, or join metal sheets to PCB or plastic panels. Their rotational capability offers additional application advantages by allowing the fastener to act as a hardened pivot point. SpotFast fasteners install smooth with the top sheet and flush or sub-flush with the bottom sheet.

Click here to learn more. |

| | Feature articles |

| Magnesium: The lightweight contender for modern parts

Magnesium is the lightest usable structural metal, widely available and easy to produce, so no wonder it is steadily replacing iron, other metals, and even plastic in an increasing number of applications. It's nearly as strong as aluminum and about one-third lighter, giving it a significant strength-to-weight advantage. Gus Breiland, Customer Service Engineering Manager from Proto Labs, runs through the fabrication methods for magnesium, design and prototyping considerations, corrosion and safety issues, and the basics of thixoforming -- a high-speed injection-molding process that is gaining in popularity.

Read the full article. |

|

| Are U.S. Army modernization efforts in a 'death spiral'?

As the budget comes down and programs are extended, smaller quantities of items are purchased, driving up cost. Organic industrial workers are sitting on their hands with less work coming in. Small businesses that produce critical system components that the Army can no longer afford risk bankruptcy. "This is a death spiral we're in now," said Heidi Shyu, assistant secretary of the Army for Acquisition, Logistics, and Technology, describing the state of Army modernization recently.

Read the full article. |

| UA researchers create cheap do-it-all camera for future Mars rovers

University of Arizona engineers have turned an off-the-shelf digital camera into an imaging device that could be key in the search for life forms on other planets. Mounted on a rover like NASA's Curiosity, the Astrobiological Imager could someday help identify promising spots to search for traces of life. Unlike existing imagers, the prototype developed by the UA-led team can photograph things close up and far away.

Read the full article. |

| Mike Likes:

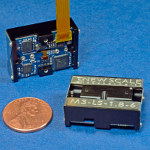

New micro stage kit aids development of handheld, portable, and mobile instruments

New Scale Technologies has made the developer's kit for its tiny M3-LS Linear Smart Stage available on DigiKey and Mouser. The M3-LS Linear Smart Stage is a direct-drive, high-precision micro stage built for fast, simple integration into miniature OEM systems. Closed-loop positioning is achieved with an integrated absolute encoder with 0.5-µm resolution. This stage does not require homing or zeroing at first power-up. All drive and control electronics are inside the 29 x 20 x 10 mm micro stage and can be commanded directly by the OEM's system processor over a standard serial interface.

Click here to learn more. |

| Products: Heavy-duty actuators for rugged environs

Southco has recently expanded its successful line of mechanical actuators with two new styles that provide reliable actuation in heavy-duty applications. Constructed of high-strength, corrosion-resistant materials, AC-10 and AC-15 Actuators are designed for use in rugged exterior environments where remote actuation of a latch is critical. The AC-10 features flush-mount installation and provides direct, single, or multipoint actuation of a latch when used with cables. The AC-15 provides direct actuation and features a surface-mount design to minimize protrusion. Both are available in locking and non-locking versions.

Click here to learn more. |

| Products: Replace worn sealing surfaces

New-generation SKF Speedi-Sleeves used with radial shaft seals in rotating machinery resolve the micro-cracking issues typically associated with conventional chrome-plated sleeves. These sealing solutions enable users to quickly and efficiently replace worn sealing surfaces without requiring time-consuming and unproductive machine disassembly and subsequent shaft regrinding. SKF Speedi-Sleeves install easily on shafts without using special equipment and can return machinery to service within minutes at a fraction of the cost of traditional shaft reworking.

Click here to learn more. |

| Products: Electric replacement for hydraulics

The Tolomatic RSA-HT high-force rod-style actuator is designed for high-duty-cycle performance in demanding applications, while delivering the added control and consistency of an electric drive actuator. This actuator, which can also be considered as a replacement for hydraulic applications, triples the maximum force capabilities of the standard RSA line from 4,038 lbf (17.96 kN) to 12,900 lbf (57.38 kN).

Click here to learn more. |

| Products: Keep 3D-printed parts from warping

Wolfbite from Airwolf 3D is a new premium solution specially engineered to bond Acrylonitrile Butadiene Styrene (ABS) plastic parts to a heated 3D-printer build plate without lifting (also known in the industry as "warpage") and to enable the smooth release of objects after printing. Wolfbite is applied with an applicator brush straight onto the glass, eliminating the need for PET film or Kapton tape. One light coat of Wolfbite can be used for several prints.

Click here to learn more. |

| | Videos+: Technologies and inspiration in action | Smashing pumpkins: The physics behind punkin chunkin

Learn how the American Chunker team won last year's national Punkin Chunkin Championship with ingenuity and engineering skill, and how they continue to revolutionize the sport by staying ahead of the competition with new ideas and CAD-embedded testing in SOLIDWORKS Simulation.

View the video. |

|

|

|