| February 10, 2015 | Volume 11 Issue 06 |

|

| Completely Updated New Full Line Catalog:

Full of New Fasteners

Micro Plastics introduces its new 300-page catalog #40 containing thousands of fastening solutions for engineers and product designers. Find hundreds of new problem-solving products, including Spacers, Washers, Clips, Clamps, Ties, Bushings, Screws, Nuts, Rivets, and Plugs. Micro Plastics specializes in Nylon threaded fasteners, but the company also offers extensive product lines for wire management and circuit board hardware. FREE samples are available upon request.

Click here for more information. |

| Could this be the world's most effective wedge-locking washer?

You can count on one solution to meet all your bolt-securing needs using the just-introduced Nord-Lock X-series washers. They combine Nord-Lock's unrivaled wedge-effect solution (to prevent spontaneous loosening) with an exceptional spring effect (to compensate for loss of preload due to slackening). When used in pairs, each washer duo has cams on one side and radial teeth on the opposite side to secure the bolted joint with tension instead of friction. Quick and easy to install and remove with standard tools, this is a great solution for handling vibration and dynamic loads, painted or powder-coated surfaces, soft metals, and composites and polymers.

Click here to learn more. |

| | Feature articles | Can you handle the ultimate product teardown?

Design for Manufacture and Assembly (DFMA) from Boothroyd Dewhurst is an intense teardown tool that focuses on benchmarking, Lean, and Total Cost of Ownership (TCO) methodologies to redesign products with reduced part counts and simplified assembly. Read about how oil and gas equipment producer Viatran used this powerful process and software to redesign a hammer-union pressure transmitter with radical results -- and ask yourself if your products are ready for this kind of heavy-duty scrutiny. Design for Manufacture and Assembly (DFMA) from Boothroyd Dewhurst is an intense teardown tool that focuses on benchmarking, Lean, and Total Cost of Ownership (TCO) methodologies to redesign products with reduced part counts and simplified assembly. Read about how oil and gas equipment producer Viatran used this powerful process and software to redesign a hammer-union pressure transmitter with radical results -- and ask yourself if your products are ready for this kind of heavy-duty scrutiny.

Read the full article. |

|

|

|

| Mike Likes: Raspberry Pi 2 Model B - 6X faster

The Raspberry Pi 2 Model B credit card-size computer is six times faster than the previous model and now boasts 1 GB of RAM to run bigger and more powerful projects. This fast-boot, single-board computer is just screaming for your projects, featuring a quad-core processor running at 900 MHz. All previous Raspberry Pi projects are compatible with the new Raspberry Pi 2 Model B, and the expanded GPIO pins, advanced power management, and connectivity make it possible to connect up to four USB devices. All this, and the board is still 35 bucks! Since its launch in February 2012, over 4 million Raspberry Pi boards have been sold.

Click here to learn more. |

| Engineer's Toolbox:

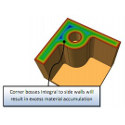

6 plastic product design principles

The rapid development of modern 3D CAD systems has facilitated a move to more organic forms and ever-increasing geometry complexity. Just think about the change in design from the conventional box-shaped vacuum cleaner to the modern Dyson. This article focuses on design fundamentals like wall thickness, rib designs, and draft angles and the impact they have when it comes to complexity vs. manufacturability.

Read the full article. |

| Favorite Materials: Copper foam

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial Designfax favorite.

Click here to learn more. |

| Product: Flyweight motor, heavyweight performance

In the fight for high performance with minimum weight, FAULHABER's 3274 BP4 available from MICROMO is the new champion in the ring. This brushless DC servo motor, measuring 32 mm in diameter and 74 mm in length, has massive continuous torque of 165 mNm. Surprisingly, it weighs in at just under 320 g, which is half the weight of conventional motors with comparable power.

Click here to learn more. |

| Product: Keep 3D-printed parts from warping

Wolfbite from Airwolf 3D is a new premium solution specially engineered to bond ABS plastic parts to a heated 3D-printer build plate without lifting (also known in the industry as "warpage") and to enable the smooth release of objects after printing. Wolfbite is applied with an applicator brush straight onto the glass, eliminating the need for PET film or Kapton tape. One light coat of Wolfbite can be used for several prints.

Click here to learn more. |

| Product: Spring-loaded plunger assemblies serve as positioning pins for sliding components

PEM Type PTL2 spring-loaded plunger assemblies from Penn-Engineering ideally serve as reliable positioning pins to quickly move racks, slides, access panels, consoles, and similar equipment to new positions without requiring tools. A unique lockout feature in the standard product line keeps the fastener's spring-loaded plunger fully retracted until the plunger pin drops into final position. These plunger assemblies install permanently in aluminum or steel sheets as thin as .060 in./1.53 mm with hardness of HRB 80 or less. Their engineering allows the reverse side of the sheet to remain flush when the plunger is retracted.

Click here to learn more. |

| | Most popular last issue |

| Wheels:

3D-printed Shelby Cobra born from giant additive manufacturing machine (Wow!)

It took six weeks for designers, engineers, and finish techs at Oak Ridge National Laboratory to put together a fully drivable 3D-printed Shelby Cobra replica. The bright blue sports car, a celebration of the racing car's 50th anniversary, was hurriedly prepared in the short term for a debut at the 2015 North American International Auto Show in Detroit this past January. In the long term, the feverish efforts have produced a working lab on wheels that aims to become a plug-and-play testbed for new engine, fuel cell, and battery technologies.

Read the full article. |

|

| | Videos+: Technologies and inspiration in action | World-record Rubik's Cube solver is Lego robot

Think the world's fastest Rubik's Cube solver is a DARPA-funded droid made by fresh, young MIT researchers? Think again. The fastest robotic cube solver is a Lego contraption. Just how fast? 3.253 seconds. The CUBESTORMER 3 robot, the result of 18 months of spare-time effort by U.K. co-inventors David Gilday and Mike Dobson, employs a Samsung Galaxy S4 smartphone powered by a bunch of extra processors. The phone analyzes the cube, calculates the correct sequence of moves, and instructs four robotic hands to do the manipulations. ARM9 processors also power the eight LEGO MINDSTORMS EV3 bricks that perform the motor sequencing and control. This machine won its Guinness World Record title back in March 2014, but we thought it was well worth a second look. Gilday and Dobson held the previous solve-time record of 5.27 seconds using their CUBESTORMER 2 creation.

View the video. |

|

Windshield wrapping: Toyota takes on parts packaging

See how a simple change in packaging and handling windshields at Toyota made a huge difference in damage control. Associates at the parts center in Kentucky now use less packaging when shipping windshields, and the packaging material is clear for easy inspection through every step of the storage and delivery process. Brilliant! This is one way Toyota reduced or recycled over 780 million lb of waste last year and improved workflow significantly.

View the video. |

|

|

|