| April 14, 2015 | Volume 11 Issue 14 |

|

| Completely Updated New Full Line Catalog:

Full of New Fasteners

Micro Plastics introduces its new 300-page catalog #40 containing thousands of fastening solutions for engineers and product designers. Find hundreds of new problem-solving products, including Spacers, Washers, Clips, Clamps, Ties, Bushings, Screws, Nuts, Rivets, and Plugs. Micro Plastics specializes in Nylon threaded fasteners, but the company also offers extensive product lines for wire management and circuit board hardware. FREE samples are available upon request.

Click here for more information. |

| Cable protection without application restraint!

The Triflex R Energy Chain System from igus is a multi-axis cable carrier built for a range of applications. With 3 dimensional flexibility in a range of protection levels, Triflex R is perfect for lightweight to heavy duty applications. The high tensile strength of Triflex R means even applications on six-axis robots with complex configurations are possible. The modular design also enables cables and hoses to be separated, optimizing service life and minimizing downtime.

Click here to learn more. |

| Mike Likes:

Lightweight high-density zipper-fin heat sinks

New zipper-fin heat sinks from Advanced Thermal Solutions (ATS) are protecting thousands of components from the dangers of excess heat at a lower cost than other high-fin-density heat-sink types. Zipper fins are machined from thin sheet metal, typically aluminum or copper, and are formed into custom shapes. Zipper-fin sinks can be designed with integral ducts to contain and optimize cooling airflow for LEDs as well as hot components in the telecom, datacom, military, and embedded electronics industries.

Click here to learn more. |

| Engineer's Toolbox:

Plastic used for jet-fighter fuel housing

In the manufacturing of complex fuel housings for the global aircraft industry, cost savings of more than 30 percent and weight savings of up to 50 percent can be achieved compared to existing metal designs. The efficient production, including part consolidation, is the result of Egmond Plastic, a leading injection-molding specialist, combining their own fusible-core technology with a high-performance PEEK polymer solution provided by Victrex.

Read the full article. |

| High-hardness 3D-printing materials

If your vision of the future is 3D printing your own high-hardness steel bearings right at your location on demand, your wish has been granted. A new development from the NanoSteel Company supports the market need for on-demand, on-site wear parts while addressing the current challenges in 3D printing of high-hardness parts. NanoSteel's powder alloy overcomes one of the major hurdles to achieving a high-hardness metallic part through additive manufacturing: the tendency to develop cracks during part builds. The company worked with a global process development partner to optimize processing of a proprietary NanoSteel alloy with a high volume fraction of borocarbide phases. This successfully produced a fully dense (99.9 percent) crack-free part with hardness values over 1000 HV, wear resistance comparable to conventionally manufactured M2 tool steels, and a uniform microstructure.

Click here to learn more. |

| Structural adhesives for vehicle assembly

SCIGRIP provides transportation design engineers with a series of structural adhesives specifically formulated to provide tough, durable bonds for a wide range of metal, thermoset composites, and thermoplastic substrates. These low-VOC methacrylate adhesives bond metal, composites, and plastics to enable quicker, more economical, and less labor-intensive assembly operations than mechanical joining methods or welding techniques. SCIGRIP adhesives are available in several product series with a variety of curing times, from products that set in as little as 4 to 6 min. for relatively small applications, or as long as 15 to 40 min. for more complicated assemblies requiring precise positioning.

Click here to learn more. |

| Low-cost hexapod 6-axis positioner

The PI H-820 hexapod from Physik Instrumente (PI) was developed for applications that require multi-axis motion and high flexibility but do not need sub-micron precision. This new model caters to these needs with linear travel to 100 mm, rotary travel to 60 deg, and a load capacity of 20 kg. High velocity and long service life are guaranteed by direct-drive brushless servo motors. Position repeatability is in the low micron range. A controller and software are included with all PI hexapods.

Click here to learn more. |

| Cool Tools: Creaform GO!SCAN 3D scanner

Creaform's Go!SCAN 3D is a simple, portable, and affordable 3D scanner that lets engineering users effortlessly capture the 3D shape of any object, including complex, freeform, and organic shapes. This is a really slick tool that lets you scan using a super-easy spray-paint motion style for accurate reverse-engineering or prototyping models. Dynamic referencing makes it possible to move the part during scanning, all while keeping the accuracy level up to 0.1 mm.

View the video. |

| | Videos+: Technologies and inspiration in action | Festo 3D-printed BionicANTs exhibit cooperative behavior

Like their natural role models, Festo's 3D-printed BionicANTs work together under clear rules. They demonstrate how autonomous individual components can solve a complex task working together as an overall networked system. The laser-sintered components are embellished with visible conductor structures. Festo -- a pneumatics and electrical automation company -- leverages the benefits of piezo technology for the actuator technology used in the legs. The bending actuators can be controlled quickly and precisely, work on little energy, and do not need much space.

View the video. |

|

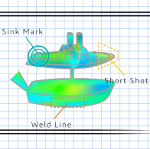

Fundamentals of SOLIDWORKS Plastics

Validating your plastic part designs with SOLIDWORKS Plastics will ensure proper fill, determine best gate location, and eliminate potential defects and improve part quality. Take a look at this intro to the software.

View the video. |

|

|

|