| July 21, 2015 | Volume 11 Issue 27 |

|

| Design Cube from Proto Labs

Our Design Cube illustrates important considerations when designing plastic injection molded parts. It showcases a range of available surface finishes and examples of bosses, gussets, and ribs. It also demonstrates the impact on part quality of overly thick or thin sections, as well as ways to incorporate holes and their potential effect on resin flow.

Register today and get yours free! |

| | Feature articles |

| Product simplification: Rediscover a whole new game

Product simplification is the discipline of merging the greatest performance functionality into the fewest number of parts using the most suitable and cost-effective materials and manufacturing processes. It is an engineering board game, in a way, says John Gilligan, President, Boothroyd Dewhurst, answering questions about a design and seeing a Design for Manufacture and Assembly (DFMA) database respond with quantitative costs and reports.

Read the full article. |

|

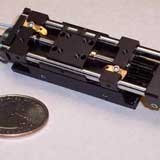

| Ultra precision for linear and rotary positioning

Tabletop devices for lab automation, instrumentation, biotech, and semiconductor manufacturing require precise, repeatable, and highly accurate motion control for stage positioning. The motorized MicroMini stage is powered by compact micro servo motors and exceeds the high demand for precision positioning, offering +/-3 µm accuracy and +/-2 µm repeatability over 5 mm of travel, even under heavy-duty cycles of a commercial lab.

Read the full article. |

| Super-impressive nonstick coating slides into market

The days of wasting condiments -- and other products -- that stick stubbornly to the sides of their bottles may be gone, thanks to MIT spinout LiquiGlide, which has licensed its nonstick coating to a major consumer-goods company. LiquiGlide is a liquid-impregnated coating that acts as a slippery barrier between a surface and a viscous liquid. Applied inside a condiment bottle, for instance, the coating clings permanently to its sides, while allowing the condiment to glide off completely, with no residue.

Read the full article. |

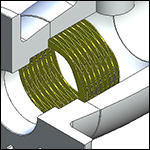

| Mike Likes: Wave Spring 3D Models

CAD models of Smalley Wave Springs are downloadable at application-specific heights. Enter any height between the spring solid and free height in over 60 native and natural CAD formats. Wave springs can reduce spring height by up to 50% with the same force and deflection as coil springs.

Click here to learn more. |

| Connectors: Lightweight terminations for aerospace

New COPALUM Lite sealed terminals and splices from TE Connectivity provide up to 60 percent in weight savings versus copper terminal alternatives, and up to 53 percent weight savings versus drop-forged aluminum terminals. The new terminals feature the time-tested dry crimp technology that has provided three decades of reliable connectivity to the commercial aerospace industry.

Click here to learn more. |

| Adhesives: Improved mold fouling, prebrake resistance

LORD Chemlok 6270 bonds a variety of rubbers including natural rubber, nitrile, and EPDM to multiple substrates including aluminum, brass, and grit-blasted or phosphatized steel when used in combination with Chemlok primers. This adhesive offers improved bonding performance and mold fouling, as well as premium environmental and prebake resistance. Uses include seals, gaskets, bushings, mounts, industrial tires, rolls and rollers, as well as seismic and bridge bearing pads.

Click here to learn more. |

| Cool Tools: Smart Tweezers troubleshoot PCBs

The LCR-Reader from Siborg Systems is an affordable and convenient alternative to traditional testers. Using just one hand to hold the rechargeable 1-oz device like a pen makes it easy to concentrate on the component being measured. LCR-Reader automatically determines the type of component and the best range and frequency before quickly delivering the values on the display. Along with the main impedance value, the secondary impedance component is also shown as well as the component type, measurement mode, and test parameters. The gold-plated probes ensure a reliable contact grasp on all components down to a 0201 size. Under 200 bucks.

Click here to learn more. |

| Motors: Big features in limited spaces

The smallest Lexium MDrive integrated motor, 1.7-in./42-mm NEMA size 17, delivers a vast range of features to small spaces, including M12 connectors and IP65 certification. These feature-rich products from Schneider Electric Motion USA outperform many larger motors, delivering up to 2x the motor torque with hMT closed-loop technology. hMT never loses functional control of the motor, so derating a motor's max torque by 50 percent to prevent stalling can be eliminated. NEMA 17 Lexium MDrive products are well-suited for both new and existing applications and fit neatly into small spaces, while reducing system wiring by up to 40 percent.

Click here to learn more. |

| | Videos+: Technologies and inspiration in action | GE engineers fire up mini 3D-printed jet engine

Engineers at GE Aviation made a simple 3D-printed mini jet engine and then had it roar to life at 33,000 rpm. The backpack-size screamer was built over the course of several years to test 3D printing's capabilities with metal and high-strength, high-temperature alloys. "We wanted to see if we could build a little engine that runs almost entirely out of additive manufacturing parts," said Steve Grimm, the plant leader at the Additive Development Center outside Cincinnati, in a GE Reports interview. "This was a fun side project."

View the video. |

|

|

|