| August 25, 2015 | Volume 11 Issue 32 |

|

| Molded Nylon Special Standard Round Spacers

Micro Plastics announces a new product line of Special Standard Round Spacers. The new line of molded nylon round spacers includes over 250 sizes, with diameters of 1/8" through 1 1/2" and lengths from 1/8" to 2 3/4". These tough, resilient spacers can be used in a variety of assemblies. Useful in electronic and electrical applications, they may also be used as bushings, bearings, rollers, gliders, and bumpers. They are resistant to vibration, abrasion, and corrosion; are electrically insulating; and have a high strength-to-weight ratio.

Click here to learn more. |

| | Feature articles |

| Tiny inverse-Wankel rotary engine concept is 4-lb powerhouse

Noise, excessive vibration, and relative inefficiency are drawbacks of the piston-based internal combustion engines (ICEs) that power today's lawn and garden equipment, such as leaf blowers and lawn trimmers. But now MIT startup LiquidPiston has developed a 4-lb rotary concept that it says is significantly smaller, lighter, and quieter, as well as 20 percent more fuel efficient than the ICEs used in many such small-engine devices.

Read the full article. |

|

| New GE research center aims to take 3D printing to a whole new level

On Oct. 6, 2014, a Boeing 747 modified for testing jet engines taxied along a concrete runway on the edge of the Mojave Desert and took off with a brand new engine strapped to its left wing. Although the engine's maiden flight was short, it made aviation history. For the first time, the GE engine, called LEAP, flew with 19 fuel nozzles 3D printed by a computer-guided laser from layers of metal powder. "You couldn't make this nozzle any other way," says Greg Morris, a 3D-printing pioneer who leads additive manufacturing research at GE Aviation. Now GE is spending $32 million to build a new research and education center in Pennsylvania focused on pushing the envelope of additive-manufacturing technologies.

Read the full article. |

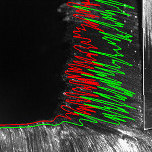

| Energy needed to cut some metals halved with simple solution

The discovery of a previously unknown type of metal deformation -- sinuous flow -- and an easy method to suppress it could lead to more efficient machining and other manufacturing advances by reducing the force and energy required to process metals. Findings from researchers at Purdue University showed that cutting force can be reduced 50 percent and that machining can probably be achieved faster and more efficiently, and with improved surface quality.

Read the full article. |

| Mike Likes: Rapid manufacturing for metals

Proto Labs' latest materials-focused white paper explores metal properties and the molding, machining, and 3D-printing processes used to manufacture quick-turn parts. The paper examines materials ranging from soft metals like aluminum and magnesium to hard metals like steel and stainless steel. Learn which materials bring added strength, reduced weight, and other benefits that help determine the right path to metal prototypes and low-volume production parts.

Click here to learn more. |

| Cable Protection: The right material for your application

While cable management is often an afterthought for many design engineers, adequate cable carrier systems are many times the key to protecting important energy supply systems on automated machinery, not only guiding cables and hoses, but protecting them from external elements such as dirt and dust, hot chips, chemicals, and excessive heat. In this material guide from igus, learn the different options available to make the most of your cable management, no matter how challenging the application.

Click here to learn more. |

| Mechanical: Prototype and repair collar system

The SPARC rapid prototype and repair collar system from Stafford Manufacturing lets users create their own working prototypes of special-purposed shaft collars within a few hours. It features precision-machined shaft collar masters that are available from stock and accept 3D-printed inserts. Combining the clamping strength of a conventional, machined shaft collar with the flexibility of unlimited insert configurations, users can create custom-designed inserts with bores to fit virtually any type of shaft and can include holes, bosses, slots, tabs, hubs, pulleys, and other features.

Click here to learn more. |

| Fasteners: Self-clinching blind nuts feature 'closed-end' design

PEM self-clinching blind nuts from PennEngineering permanently install into thin metal sheets to provide reliable and reusable metal threads for accepting mating screws and completing final component attachment in an assembly. Their "blind," closed-end design effectively creates a barrier to protect the nut's threads against foreign matter and to prevent potential damage to internal components from mating screws. The carbon steel (Type B) and stainless steel (Type BS) nuts install quickly and permanently into aluminum or steel sheets as thin as .040 in./1mm. No secondary operations are required.

Click here to learn more. |

| Motors: Demanding operating room applications

maxon's new brushless electric motor, the EC-4pole 30, delivers high torque (106 mNm) and is sterilizable -- a perfect drive for handheld surgical tools. Featuring two pole pairs, this DC motor provides a nominal torque of 106 mNm and an output of 150 W. It has a hermetically sealed rotor, meaning that it can withstand over 1,000 autoclave cycles. The EC-4pole 30 is equipped with the special ironless maxon winding, which makes it highly efficient. Another key feature is that the torque and current behave linearly, and the drive can be overloaded. It is available with an optional Hall sensor, as well as with a hollow shaft with a diameter up to 4.1 millimeters.

Click here to learn more. |

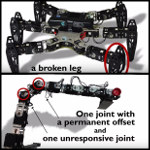

| | Videos+: Technologies and inspiration in action | Can robots learn and adapt like animals?

Jean-Baptiste Mouret, an assistant professor of artificial intelligence and robotics at Pierr & Marie Curie University in Paris, France, has developed an algorithm that allows robots to "learn," through trial and error, ways to compensate for challenges like broken arms or legs. This video demonstrates how the Intelligent Trial-and-Error Algorithm works to help two robots adapt to challenging situations in under 2 minutes -- with surprisingly lifelike results.

View the video. |

|

Solid Edge ST8 Synchronous Design Intent

This Siemens PLM demonstration highlights the new interface for intuitive synchronous modeling, helping you to focus more on your design and less on the software. Synchronous technology in Solid Edge allows sophisticated wholesale moves of geometry "chunks" without regard for feature history. In Solid Edge ST8, QuickBar options control how a chunk interacts with surrounding geometry during the move.

View the video. |

|

|

|