| October 13, 2015 | Volume 11 Issue 38 |

|

| Completely Updated New Full Line Catalog:

Full of New Fasteners

Micro Plastics introduces its new 300-page catalog #40 containing thousands of fastening solutions for engineers and product designers. Find hundreds of new problem-solving products, including Spacers, Washers, Clips, Clamps, Ties, Bushings, Screws, Nuts, Rivets, and Plugs. Micro Plastics specializes in Nylon threaded fasteners, but the company also offers extensive product lines for wire management and circuit board hardware. FREE samples are available upon request.

Click here for more information. |

| White Paper: Seven Key Enabling Application Technologies For A Wide Range Of Engineering Applications

Metal bellows play an essential role in controlling pressure, vacuum, motion and more in a broad array of machine components and assemblies across numerous industries. The whitepaper showcases seven engineering applications that can benefit from the use of bellows, and demonstrates the broad functionality of bellows in different engineering scenarios. Engineers are provided with important specifications (in terms of requirements and restrictions) that must be considered for an application.

Read more ... |

| | Feature articles |

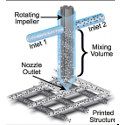

| Advances in multimaterial printheads pave way for next frontier in 3D printing

The ability to integrate disparate materials and properties within printed objects is the next frontier in 3D printing. Toward this objective, Harvard researchers have designed new multimaterial printheads that mix and print concentrated viscoelastic inks that allow for the simultaneous control of composition and geometry during printing. Using active mixing and fast-switching nozzles, these novel printheads change material composition on the fly and could pave the way for entirely 3D-printed wearable devices, soft robots, and electronics.

Read the full article. |

|

| Space:

NASA tests acrylics for Orion spacecraft windows

When astronauts travel to an asteroid and toward Mars in NASA's Orion spacecraft, they'll get a tremendous view of their deep-space destinations and of Earth through the spacecraft's windows. NASA engineers are making sure those windows will be more structurally sound, lighter, and cheaper than on previous spacecraft.

Read the full article. |

| Mike Likes: 3D printer uses paper not plastic

The Mcor IRIS HD provides 360-degree high-definition color, sharpens details, and reduces the industry's already lowest operating costs for 3D printing by 20 percent. How can one printer do all that? It uses paper to make the models: 1. Each layer of a design is printed on a sheet of paper using high-saturation inks. 2. The stack of paper is put into the "printer," where each piece is carefully edge-glued with special adhesives and cut. 3. The model stack grows. 4. Pop your finished color model out of the precision glued and cut stack. Paper-based 3D models are serious prototyping contenders, because the model cost is so low: often around 10 bucks or less a pop.

Learn more about Mcor Technologies and their unique 3D printers. |

| Engineer's Toolbox:

How topology optimization can create better material, design in high-consequence uses

Sandia National Laboratories researchers believe that organically shaped designs, achieved through a technology called topology optimization, could enable better parts for national security systems and other vital uses. Coupled with advanced additive manufacturing, familiar to most people in its 3D-printing incarnation, it opens possibilities for complex shapes that conventional manufacturing methods can't handle. Along the way, researchers are doing some serious questioning and testing of the tiniest details of what really happens to materials when they are 3D printed.

Read the full article. |

| Why plastic bearings outperform metal

Plastic bearings cost and weigh less than their metal counterparts. And they often run longer in harsh environments and under adverse conditions. Plain bearings molded of plastic are often an economical replacement for needle, ball, and plain metal bearings. To a certain extent, though, plastic bearings face an uphill battle for respect among the engineering community.

Learn more in this White Paper guide from igus®. |

| Motors: Simplified small motor load overload protection

Power management company Eaton has launched a competitively priced, enclosed manual motor starter with hand-off-auto (HOA) functionality and run-light indication. Designed to meet the needs of contractors, original equipment manufacturers (OEMs), and distributors in the construction and HVAC markets, this compact, cost-effective package solution is designed to enable both local and remote-control capabilities of 1-hp, single-phase motor applications where overload protection is required. With this compact solution, customers will no longer need to order three separate parts to assure overload protection for small motor power loads up to 16 A at 120 V to 240 V.

Click here to learn more. |

| Carbon fiber composite for robust vehicle parts

Covestro (formerly Bayer MaterialScience) has developed a new Baydur matrix system for carbon fiber structural components in cars that has three times the energy absorption potential of comparable resins, so it is able to provide an extremely high level of occupant safety in the event of a collision. Covestro expert Karine Benbelaid shows the prototype of a component, which was manufactured using the efficient high-pressure resin transfer molding process (HP-RTM). The HP-RTM process has proved very effective for manufacturing robust composite parts in volumes in the low hundreds of thousands. Carbon fiber content is approximately 54% by volume.

Click here to learn more. |

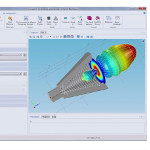

| COMSOL version 5.1 is here

Modeling and simulation is now a reality for everyone thanks to COMSOL Multiphysics version 5.1. The Application Builder and COMSOL Server have both been dramatically improved to enhance the simulation experience for you -- and even for your colleagues who do not have a background in simulation. Furthermore, COMSOL Multiphysics and its add-on modules have also been improved. Browse through the release highlights to find out what is new or download COMSOL version 5.1 to utilize the latest technology in simulations today.

Click here to learn more. |

| | Most popular last issue |

| High-speed 3D printing aims to take on injection molding

The world's first additive manufacturing (3D-printing) machine that can make plastic parts as fast and cheaply as traditional manufacturing is being built by the University of Sheffield in the UK. The machine will build parts up to three times larger and 100 times faster than current comparable additive manufacturing (AM) machines, making it capable of challenging conventional injection molding for high-volume production.

Read the full article. |

| Wheels:

Ford F-150 features super alloy and mega-fast aluminum processing

Ford is using Alcoa's Micromill material in multiple components on the 2016 F-150, becoming the first automaker to use the advanced automotive aluminum, which has 40% greater formability and 30% greater strength than the incumbent aluminum used today, commercially. On the process side, a traditional rolling mill takes around 20 days to turn molten metal into coil; Micromill does it in just 20 minutes.

Read the full article. |

|

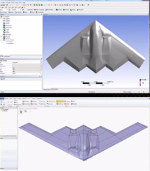

| | Videos+: Technologies and inspiration in action | Stealth and aerodynamic design

ANSYS solutions enable the creation of complete virtual prototypes for the exploration of the trade space between aerodynamics, propulsion intakes, and radar cross-section performance of advanced stealth aircraft, subsystems, and components. This enables companies and engineers to develop products faster, test designs earlier in the development cycle, reduce the number of physical prototypes, and produce an optimal solution quicker. Watch the video to see ANSYS solutions in action for the integrated, multiphysics design exploration of aerodynamic, observability, and propulsion system performance of a representative generic stealth aircraft.

View the video. |

|

What does Alka Seltzer do in space?

Astronauts on the International Space Station dissolved an effervescent tablet in a floating ball of water and captured images using a camera capable of recording four times the resolution of normal high-definition cameras. The higher resolution images and higher frame rate videos give researchers a valuable new tool aboard the space station. This footage is one of the first of its kind. The cameras are being evaluated for capturing science data and vehicle operations by engineers at NASA's Marshall Space Flight Center in Huntsville, AL.

View the video. |

|

|

|