| July 26, 2016 | Volume 12 Issue 28 |

|

| Smartest, toughest cable tie out there

The DualZip cable tie from Micro Plastics combines the functionality of both a releasable and a permanent tie in one part. The permanent lock is so strong that, under normal circumstances, the part will fail with the strap breaking before there is slippage within the lock. The releasable lock can be ratcheted and released many times and will continue to reliably lock. With this design, the teeth are on the outside of the bundle diameter, making it easy to release, and the release tab is located up and away from the bundle for easy access every time. The DualZip Cable Tie is available in 8-in. length. Free samples available on request.

Click here to learn more. |

| Direct Metal 3D Printing: The hottest thing in additive manufacturing

Build complex, REAL metal parts from 3D CAD data, while getting industry-leading part quality, fine details, precision and repeatability. The Direct Metal Printing process from 3D Systems is an additive manufacturing technology that builds fully dense, chemically pure complex metal parts that often can't be achieved through traditional machining.

Learn more.

|

| | Feature articles | Countering the reappearance of old-school views on product design

In the early 1980s, a product design methodology called Design for Assembly (DFA) began to gain popularity. In the past 10 years, there has been a significant resurgence in a different design philosophy -- a very old and outdated one -- that is skewing the productivity gains companies achieved through DFA. Using real-world examples, Boothroyd Dewhurst's Brian Rapoza describes how to -- and how not to -- cut costs during part redesigns. In the early 1980s, a product design methodology called Design for Assembly (DFA) began to gain popularity. In the past 10 years, there has been a significant resurgence in a different design philosophy -- a very old and outdated one -- that is skewing the productivity gains companies achieved through DFA. Using real-world examples, Boothroyd Dewhurst's Brian Rapoza describes how to -- and how not to -- cut costs during part redesigns.

Read the full article. |

|

|

|

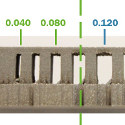

| Design Tips: Metal 3D printing and the ABCs of building in support structures

If you're ready to climb aboard the direct metal laser sintering (DMLS) express, there are a few things you should know first. Although the technology produces fully dense parts from high-strength, corrosion-resistant metals, certain part features are prone to warping and curl if not supported properly during the build process. Gus Breiland, Customer Service Engineering Manager, Proto Labs, gives us some valuable advice.

Read the full article. |

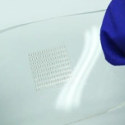

| Scientists develop plastic flexible magnetic memory device

It looks like a small piece of transparent film with tiny engravings on it, and it's flexible enough to be bent into a tube. Yet, this piece of "smart" plastic -- aimed at the burgeoning flexible electronics market -- demonstrates excellent performance in terms of data storage and processing capabilities: 1,000 times faster than typical FLASH memory and 100 times more storage capacity than FLASH.

Read the full article. |

| CNC Machining Material Selector!

Proto Labs' free Material Selector is a quick reference guide to help you identify the right thermoplastic and metal materials for your next machining project. It lists specific measurements like tensile strength, heat deflection and hardness to ensure you have the most suitable material for your part's application, and even includes a detailed chart of threading options.

Get a free Material Selector today! |

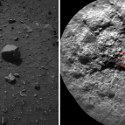

| Mars rover's laser can now target rocks all by itself

New software is enabling ChemCam, the laser spectrometer on NASA's Curiosity Mars rover, to select rock targets autonomously -- the first time autonomous target selection is available for an instrument of this kind on any robotic planetary mission. Having a smarter rover that can pick its own samples is in line with self-driving cars and other smart technologies being implemented on Earth.

Read the full article |

| Mechanical: Low-cost thin spring engaged (power-off) brake

The Thin Spring Engaged Brake (TSEB) from SEPAC provides OEMs with a thin-body, high-performance/low-cost spring-engaged power-off brake. This solution is 60 to 70 percent thinner and up to 20 percent less expensive than conventional servomotor-type high-performance brakes. It is ideal for a wide range of OEM applications, including: servo motors/systems, medical apparatus, robotics and imaging equipment, material handling, semiconductor equipment, energy-related (wind, petroleum, etc.) actuators, and security-related actuators for doors, gates, and curtains.

Click here to learn more. |

| Outdoor Electronics: Protective vents for machinery, equipment

W. L. Gore & Associates announces two new innovative venting solutions: GORE PolyVent Stainless Steel for premium-level durability under the most challenging conditions in the field; and inside-mountable GORE PolyVent InSet for easy, cost-effective, and nearly invisible integration. GORE PolyVent Stainless Steel for screw-in installation delivers reliable oleophobic protection, flammability resistance, and the durability to withstand corrosion, chemicals, and punishing conditions in the field. GORE PolyVent InSet for snap-in installation offers fast, easy, cost-effective integration, with an inside-mount option that benefits both design and production processes and is nearly invisible when installed.

Click here to learn more. |

| Mike Likes Robotics: Tiny powerhouse of a robot

The small-but-mighty KUKA KR 3 AGILUS is aimed at production applications where very short cycle times and maximum output are required, such as assembling small components and performing handling tasks, screw fastening, brazing, adhesive bonding, packaging, testing, inspecting, and more. Payload capacity is 3 kg; reach is 540 mm. This 600 mm x 600 mm (2 ft x 2 ft) little workhorse is characterized by impressive speed and precision.

Click here to learn more. |

| Aerospace: Custom modular cooling pumps

A new family of cooling pumps from Parker Aerospace shares a common core of basic motor and pump components. The pumps are compatible with a variety of dielectric fluids including PAO, fuel, Galden, and turbine engine oils and are available in fixed- or variable-speed configurations to accommodate a variety of flow rates. Both AC and DC motor configurations are available as 115 VAC at 400 Hz, 28 VDC, or 270 VDC. The wet-motor design allows the fluid to extract heat from the electronics or the sensor suite, while also removing heat from the pump motor itself.

Click here to learn more. |

| | Most popular last issue |

| How a NASA engineer created the modern airplane wing

Once dubbed "the man who could see air," NASA engineer Richard T. Whitcomb used a combination of visualization and intuition to revolutionize modern aviation -- by turning the shape of the airplane wing on its head. Today, nearly every commercial airplane bears the marks of Whitcomb's several innovations.

Read the full article. |

|

| | Videos+: Technologies and inspiration in action |

You crushed it! See stuff get smashed

Some enterprising guys in Finland with a penchant for smashing stuff have created their own Youtube channel -- and they want to share all the fun. "Wanna see stuff getting crushed by a hydraulic press?" they ask. This is the right channel for you. From cameras to ice to an old safe, a ball bearing, a running four-stroke motor, a motorcycle helmet, and more, take a few minutes out of your day to feel like you crushed this one.

View the videos. |

|

|

|