| March 07, 2017 | Volume 13 Issue 09 |

|

| Innovative Way to Take Up Tolerances!

Smalley Linear Springs are a continuous wave-formed (marcelled) wire length produced from spring tempered materials. They act as a load-bearing device having approximately the same load/deflection characteristics as a wave spring. Linear Springs are now available as a standard part in carbon and stainless steel, with over 200 sizes.

Click here to learn more. |

| New Micro Motor Delivers Big Performance

MICROMO has just launched another new micro DC motor: the FAULHABER 1016 SR series. At 10 mm in diameter and 16 mm in length (slightly shorter than the 1024 SR), the 1016 SR series reaches a continuous torque of 0.92 mNm. Additional strengths include low power consumption, high energy-efficiency and minimal vibration & low audible noise, making it well suited for applications with small dimensions and very high requirements.

Click here to learn more. |

| Hyperloop Tech: How does a linear induction motor work?

Linear induction motor (LIM) theory is most easily understood as a rotary motor that has been cut and unrolled to generate linear motion, instead of rotary motion. It is comprised of two parts, the primary and secondary, which interact with one another only when power is applied. Either the primary or the secondary can be fixed while the other moves.

Read the full article. |

| Weird Science: Metal conducts electricity but not heat

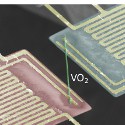

There's a known rule-breaker among materials, and a new discovery by an international team of scientists adds more evidence to back up the metal's nonconformist reputation. According to a new study led by scientists at the Department of Energy's Lawrence Berkeley National Laboratory (Berkeley Lab) and at the University of California, Berkeley, electrons in vanadium dioxide can conduct electricity without conducting heat.

Read the full article. |

| Titanium Springs from Atlantic Spring

Titanium springs from Atlantic Spring-MW Industries offer improved resistance to corrosion, lower torsion modulus, shorter free length, greater strength, and significant weight reduction over steel springs. These attributes make titanium springs ideal for various aircraft, space, military, and defense applications. Atlantic Spring offers rapid prototyping services. Prototypes can be available within 3 to 5 days dependent upon design complexity and material availability. ISO9100C certified and ITAR registered.

Download capabilities flyer. |

| Mike Likes: Discover the power of Power-Core gears

If you are interested in higher torque transmission, longer life due to lower wear, and lower creep, this is your solution. Power-Core is a proprietary unitized metal/composite material from INTECH suitable for use in long-wearing, high-performance gears, pulleys, and rollers. This lightweight material delivers quiet, lubrication-free performance that reduces gear shock and vibration and is ideal for use in hostile applications where moisture, alignment, abrasives, and/or corrosive chemicals are present. A durable metal center delivers the driveshaft torque to the special polyamide composite gearing. Build in long-term advantages by replacing metal gears with Power-Core ones. Gear-life calculations are based on experimental data collected in gear tests over 20 years.

Click here to learn more.

Learn Intech's gear calculation methods. |

| Engineer's Toolbox:

6 ways to optimize part design for CNC machining

Manufacturing prototypes and production parts fast and cost efficiently is often a balancing act of quick-turn CNC machining capabilities and an optimized part designed for those capabilities. As such, there are a handful of important considerations when designing parts for Proto Labs' milling and turning processes that can accelerate production time while reducing costs. Gus Breiland, Customer Service Engineering Manager, Proto Labs, runs through them.

Read the full article. |

| Top pick: Economy series electric actuator

The Economy Series ES (slider type) and EC (cylinder type) electric actuators are built on THK's original Linear Motion System technology for smooth and silent movement. Designed as an alternative to pneumatic cylinders and as an option for automating manual processes, these easy-to-install, compact multifunctional devices are ideal candidates for processing, assembly, transport, testing, and other applications. The ES incorporates the model SRS LM Guide, equipped with ball retainers, as well as Lubricator QZ for optimal ball-screw lubrication. The combined effect provides for long-term maintenance-free operation. Strokes available from 50 to 600 mm (ES) and 50 to 300 mm (EC), with speeds from 300 to 600 mm/s for both. Horizontal or vertical mount determines maximum load: ES = 0.5 to 10 kg (1.1 to 22 lb), EC = 3 to 15 kg (6.6 to 33 lb).

Click here to learn more. |

| Stationary field tooth clutch delivers higher torque in a smaller package

SEPAC designed the electromagnetic Stationary Field Tooth Clutch (SFTC Series) to deliver an exceptional torque-to-size ratio with the ability to operate dry or in oil. This model offers a bearing-supported design to ease the installation process. The SFTC's positive engagement, less than 1 degree of backlash, high torque-to-size ratio, and ease of installation make it ideal for a variety of applications. Additionally, the extraordinary reliability of the SFTC Series makes it a top choice for aerospace and defense actuators, aircraft flight control, military ground systems, weapon systems, elevator/azimuth, robotics, medical equipment/imaging, and more.

Click here to learn more. |

| STOBER introduces new PS Two-Speed Gearbox

STOBER Drives' PS Two-Speed Gearbox has the ability to generate both high speed and high torque, which is ideal for lathes or machining centers. This easily mountable gearbox features two different options, from a direct-drive to customer ratio choice. The 1:1 ratio direct drive can be used for high-speed cutting up to 10,000 RPM. The customer can choose from two ratios, 4:1 or 5.5:1, that are capable of turning at 7,000 RPM. This allows the customer to use a 1:1 ratio for low-torque high-speed cuts, and the 4 or 5.5:1 ratio for high-torque lower-speed cuts. STOBER offers two different output types: shafted and flanged, with three different versions of each utilizing a short, medium, or long output. Three different bearing options are also available.

Click here to learn more. |

| Complete system solutions for optimum drive and control performance

Kollmorgen's updated Automation and Motion Control catalog details the features, benefits, and specifications of the company's complete range of motion control solutions, including: Direct Drive motors, servo motors and drives, Safe Motion, distributed and central servo amplifiers, and the complete Kollmorgen Automation Suite. The catalog also includes stepper motors and drives, PMDC motors, linear actuators, and planetary gearboxes. Overall, more than 100 diverse and scalable product and solution ideas are covered in the catalog, making it much more than a simple guide for selecting individual products used in next-generation machine design.

Click here to learn more. |

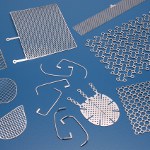

| Photo-etched thin titanium components

Tech-Etch specializes in the photo chemical etching of titanium. Because of its low weight, strength, and corrosion resistance, titanium is used in everything from jet engines to eyeglass frames. Because titanium is inert and completely biocompatible, it is also used in many medical implantation applications such as maxillofacial and craniofacial reconstruction plates, as well as anode and cathode battery current collectors and telemetry antennas found in implanted medical devices. Parts range in thickness from .0005 in. and up. While providing quick turnaround and low tooling costs, photo etching produces burr-free parts with intricate and complex shapes.

Click here to learn more. |

| | Most popular last issue |

| Next Big Thing:

Father-son team create liquid metal 3D-printing system

A father-and-son team in Amherst, NY, have invented a liquid metal printing machine that could represent a significant transformation in manufacturing. A breakthrough idea five years ago by former University at Buffalo student Zack Vader, then 19, has created a machine that prints 3D objects using melted aluminum. The nozzle design, which uses a pulsed magnetic field, is key. Printing objects in steel is in the works.

Read the full article. |

| Wheels:

Advanced combat engine aims to drive Army's energy-efficient future

The challenge in reducing vehicle fuel consumption for the U.S. Army is that few solutions exist that do not involve expensive retrofitting and fuel-reducing technologies. The U.S. Army Tank Automotive Research, Development and Engineering Center (TARDEC) is working on projects such as the advanced combat engine to meet the electrical power generation needs of future combat and tactical vehicles, a tactical vehicle electrification kit, and developing a single common powertrain lubricant.

Read the full article. |

| Lithium-ion battery research reaches for higher voltages

For years, small rechargeable lithium-ion batteries have reliably supplied billions of portable devices with energy, but standard rechargeable batteries are only marginally suited for high performance. To raise the energy density, you need to increase the voltage or the capacity, and that is where traditional electrode materials and electrolytic fluids reach their limits.

Read the full article. |

|

| | Videos+: Technologies and inspiration in action | Why air bearings over mechanical bearings?

- Air bearings are frictionless and will almost always outperform a mechanical bearing at scanning, assuming similar controls.

- Air bearings never wear out.

- A cushion of pressurized air results in surface averaging effects, meaning extremely smooth, flat, straight motion.

- Scanning performance of air bearings is not affected by speed -- very slow or very fast.

- Air bearings provide wobble-free rotary motion.

WATCH video | READ Air Bearing tech articles |

|

Updated: Handle robot jumps like an Olympian

Handle is Boston Dynamics' latest research robot. It stands 6.5 ft tall, travels at 9 mph, and jumps 4 ft vertically. It uses electric power to operate both electric and hydraulic actuators, with a range of about 15 miles on one battery charge. Handle uses many of the same dynamics, balance, and mobile manipulation principles found in other Boston Dynamics quadruped and biped robots, but with only about 10 actuated joints it is significantly less complex. Wheels are efficient on flat surfaces, while legs can go almost anywhere. Wait until you see this thing take on stairs and snow!

Watch it in action. |

|

|

|