| July 18, 2017 | Volume 13 Issue 27 |

|

| Injection Molding Material Selector!

Proto Labs' pocket-sized Material Selector is a quick reference guide to help you identify the right thermoplastic and liquid silicone rubber materials for your next injection molding project. It lists specific measurements like tensile strength, heat deflection and durometer to ensure you have the most suitable material for your part's application.

Get a free Material Selector today! |

| | Feature articles | Army vehicle-mounted laser shoots drones from sky

A Stryker combat vehicle equipped with a 5-kW laser and an array of sensors spent several minutes scanning the horizon for a wayward "enemy" drone. After a few attempts to destroy the drone with the laser, the drone fell from the sky, crashing to the ground. Not a bullet was fired, and no sounds were made by the system that accomplished the kill -- an experimental project called the Mobile High-Energy Laser.

A Stryker combat vehicle equipped with a 5-kW laser and an array of sensors spent several minutes scanning the horizon for a wayward "enemy" drone. After a few attempts to destroy the drone with the laser, the drone fell from the sky, crashing to the ground. Not a bullet was fired, and no sounds were made by the system that accomplished the kill -- an experimental project called the Mobile High-Energy Laser.

Read the full article. |

|

|

|

| Electroluminescent paint lights up the design world

It's great to have a really bright idea, but if you have one that can be spread around and lit up it's even better. Case in point is LumiLor, a light-emitting coating system from Darkside Scientific that allows anything coated with it and wired up to be illuminated. Besides providing the technology to create amazing "Tron" cars, the product's creators recently scored Airbus as a customer. Simply put, anything you paint with LumiLor can be turned on and off as easily as a light bulb.

It's great to have a really bright idea, but if you have one that can be spread around and lit up it's even better. Case in point is LumiLor, a light-emitting coating system from Darkside Scientific that allows anything coated with it and wired up to be illuminated. Besides providing the technology to create amazing "Tron" cars, the product's creators recently scored Airbus as a customer. Simply put, anything you paint with LumiLor can be turned on and off as easily as a light bulb.

Read the full article. |

| Wings: Hypersonic travel heats up with new materials discovery

Researchers at The University of Manchester in the U.K., in collaboration with Central South University (CSU), China, have created a new kind of ceramic coating that could revolutionize hypersonic travel for air, space, and defense purposes. The new carbide coating is vastly superior in resisting temperatures up to 3,000 C, when compared to existing ultra-high temperature ceramics.

Read the full article. |

| Injection Molding: 9 tips for designing multipart assemblies

Finding creative solutions to multipart assemblies can be tricky, but fortunately there are many different ways to approach product designs that involve multiple components. To keep things cost-effective and efficient, simplify your design, don't make what you can buy off of the shelf, explore all of your manufacturing options, and understand the rules of each part of the process. But like most design challenges, it's not as easy as it sounds.

Read the full article. |

| High-traction robot goes underground

Recent developments in motion control and engineering make it possible to inspect and perform maintenance in compact sewers from the inside. The underground sewer robot is equipped with a swiveling camera and an air-powered milling machine driven by FAULHABER miniature DC motors from MICROMO.

Read the full article. |

| Updated: New full line catalog of thousands of fasteners

Micro Plastics, Inc., a manufacturer of industrial-quality plastic components, has unveiled its latest product catalog containing thousands of fastening solutions for engineers and product designers. In addition to hundreds of new problem-solving products, the catalog features several new complete product lines with improved product and material explanations. Micro Plastics manufactures 10 million fasteners daily, offers over 30,000 items, and maintains an inventory of over 300 million parts. See their 300-page full line catalog #41 for a complete list of plastic fasteners currently available.

Click here to learn more. |

| OEMS and Motion Control: Optimized Performance vs. 'Good Enough'

OEMs have to balance a lot of competing factors -- cost, precision, safety, performance -- in order to build a superior machine. The motion experts at Kollmorgen discuss in depth the considerations, processes, and challenges machine engineers face when making motion-related decisions. Learn how flexibility, connectivity, modularity, changeover time, and costs can converge to create a total system approach that takes machines from 'good enough' to best in class.

Read now: Why Motion Matters |

| Proto Labs launches on-demand molded production parts service, opens metrology lab

Digital manufacturing company Proto Labs has always been known for its rapid injection molding prototyping services. Now, the company has added a suite of capabilities designed specifically to address the on-demand manufacturing needs of the low-volume, high-mix product segment. And in another company first, they've built a new metrology lab that provides enhanced inspection reporting on end-use production parts.

Read the full article. |

| World's first affordable, office-friendly metal 3D-printing system

Desktop Metal has launched an office-friendly metal 3D-printing system for rapid prototyping. The Desktop Metal Studio System is 10 times less expensive than existing technology today. The system is a complete platform, including both a printer (starting at $49,900) and microwave-enhanced sintering furnace that, together, deliver complex and even impossible geometries of metal 3D-printed parts right in an engineer's office or on the shop floor. The larger DM Production System -- 100 times faster than today's laser-based additive manufacturing systems -- is also available.

Click here to learn more. |

| World's darkest spray paint

A whole range of products can now take advantage of the world's blackest coating, Vantablack, thanks to the development of a new spray version called Vantablack S-VIS. It is easily applied at large scale to virtually any surface. Vantablack's carbon nanotube matrix structure absorbs virtually all (99.8%) incident light, enabling precision optical systems to be optimized. The material's developer, UK-based Surrey NanoSystems, has mimicked the performance of its original Vantablack with this new version that can be sprayed onto objects, rather than deposited using a chemical vapor deposition (CVD) process.

Click here to learn more. |

| | Most popular last issue |

| Most Popular Stories/Products - Part 2

Aluminum treads on Mars Curiosity rover show open breaks and tears; 2018 Dodge Challenger SRT Demon comes wheelie-ready; Army demos, flies basic 'hoverbike' prototypes; SuperTruck Update: Aerodynamics focus boosts Navistar big-rig fuel efficiency 124%; Next Big Thing in Army aviation? Lockheed Martin S-97 RAIDER is fast and furious.

Check out the full issue. |

| Most Popular Stories/Products - Part 1

Long-range sniper system is the BOSS; Air spray: The comeback of stunning military aircraft paint jobs; Camaro ZL1 tries for 200 mph on German test oval; Next Big Thing: Father-son team creates liquid metal 3D-printing system; Ford GT supercar's digital display is dashboard of tomorrow; Siemens electric airplane motor setting records left and right, up and down.

Check out the full issue. |

|

| | Videos+: Technologies and inspiration in action |

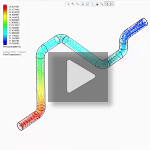

How to determine pressure drops/flow rates easily

Having embedded computational fluid dynamics (CFD) in your MCAD tool has a multitude of benefits. Among them is the ability to perform on-the-fly analyses for quick and early decision-making that can reduce simulation time by as much as 65 to 75 percent over traditional CFD tools. Take, for example, determining the flow rate and pressure drops of a vertically rising pipe. You need this kind of info to size pipes for a proposed piping system. Using FloEFD from Mentor in PTC Creo, results are quickly and easily determined when the outlet of the pipe is raised higher -- just redesign and run. In other scenarios, see how to understand flow rates using different ball-valve positions and optimize LED heat-sink fin geometry. Also works with CATIA V5, Siemens NX, Solid Edge, and SolidWorks, and it tightly integrates with Inventor.

View the video. |

|

|

|