| August 14, 2018 | Volume 14 Issue 30 |

|

| The World's First -- and Best -- Linear Motion Guides

THK's original technology is behind the smooth and silent movement of the "Linear Motion System." The LM Guide is our major product that put the rolling of the linear motion part into practical use for the first time in the world. This improves the accuracy, rigidity, energy saving, velocity, productivity, and service life of the machine. THK offers a full support system from the beginning design phase throughout the maintenance, and follow-up service.

Click here to learn more. |

| Guide to overmolding best practices

Overmolding is a great injection molded feature you can utilize in your design to capture color contrasts, add flexibility or eliminate assembly. Take advantage of this feature by learning how to design your part for overmolding.

You'll learn:

- How to set up your design for complex overmolding

- Material evaluation and best practices for proper adhesion

- Feature specifications to consider for good overmolds

Get the Xcentric overmolding guide (no registration required). |

| | Feature articles | NASA tech reduces airplane landing-gear noise

A series of NASA flight tests has successfully demonstrated technologies to address airframe noise, or noise that is produced by non-propulsive parts of the aircraft, during landing. The flights successfully combined several technologies to achieve a greater than 70 percent reduction in airframe noise.

A series of NASA flight tests has successfully demonstrated technologies to address airframe noise, or noise that is produced by non-propulsive parts of the aircraft, during landing. The flights successfully combined several technologies to achieve a greater than 70 percent reduction in airframe noise.

Read the full article. |

|

|

|

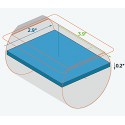

| 6 ways to optimize part design for CNC machining

Manufacturing prototypes and production parts fast and cost efficiently is often a balancing act of quick-turn CNC machining capabilities and an optimized part designed for those capabilities. As such, there are a handful of important considerations when designing parts for Proto Labs' milling and turning processes that can accelerate production time while reducing costs. Gus Breiland, Customer Service Engineering Manager, Proto Labs, runs through them.

Read the full article. |

| Significant advancements made in dry-lube tech

Researchers at the U.S. Department of Energy's Argonne National Laboratory have been working for years to replace oil with solid lubricants such as graphene. Their new process has shown that a few layers of graphene not only reduces friction in steel rubbing against steel by seven times and the wear by 10,000 times but also significantly reduces the tribo-corrosion problem.

Read the full article. |

| Download Photo Etching Precision Parts Guide

This Tech-Etch guide describes how photo etching produces prototype quantities and large production runs of precision parts for many mechanical and electrical applications, without the high cost and long lead times of hard tooling. Custom metal parts from .0005" thick and up are produced with intricate patterns, precise tolerances and burr-free edges, in addition to exact repeatability. By combining photo etching for blanking with inexpensive or universal tooling for forming, Tech-Etch produces complex designs and shapes.

Get the guide (no registration required).

|

| Mike Likes:

Handy 10 transmitter with proportional control

Scanreco Handy is a robust handheld transmitter with innovative proportional pushbuttons that are easily operated even when wearing work gloves. The speed of the controlled motion corresponds directly with the displacement of the button, enabling a higher degree of precision and performance compared to traditional one- or two-step buttons. Four proportional functions in dual directions can be controlled simultaneously. A second operational mode allows for further proportional and digital functions. Areas for function labeling with text, numbers, or symbols are located on top as well as next to each button.

Learn more. |

| Engineer's Toolbox:

Slip clutches maximize designs

The way they see it over at Polyclutch, there aren't a whole lot of problems you can't solve with a slip clutch. Way beyond using them for overload protection, there are a surprising number of other applications for these versatile and valuable components. From increasing machine speeds and applying constant tension on wire to indexing a conveyor and automatic screw assembly, slip clutches just may provide the design leverage you've been seeking.

Read the full article. |

| Problem-Solving Tips:

Screw tightening control methods

Although the main role of screws (bolts) is fastening objects using the axial force generated from tightening in actual work, there are many people who control the torque by tightening with a torque wrench, because it is difficult to directly monitor the axial force, and so guarantee the axial force that way. However, there are other methods of control for tightening screws (bolts), such as using "elastic region tightening" and "plastic region tightening."

Read this NBK technical blog. |

| A perennial reader favorite: Copper foam

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial Designfax favorite.

Click here to learn more. |

| High-hardness 3D-printing materials

If your vision of the future is 3D printing your own high-hardness steel bearings right at your location on demand, your wish has been granted. A new development from the NanoSteel Company supports the market need for on-demand, on-site wear parts while addressing the current challenges in 3D printing of high-hardness parts. NanoSteel's powder alloy overcomes one of the major hurdles to achieving a high-hardness metallic part through additive manufacturing: the tendency to develop cracks during part builds. The company worked with a global process development partner to optimize processing of a proprietary NanoSteel alloy with a high-volume fraction of borocarbide phases. This successfully produced a fully dense (99.9 percent) crack-free part with hardness values over 1000 HV, wear resistance comparable to conventionally manufactured M2 tool steels, and a uniform microstructure.

Click here to learn more. |

| Adhesives formulated in different colors

Master Bond epoxy systems are formulated in a variety of standard colors, including black, red, green, blue, gray etc. Many optically clear grades are also available. Upon request, compounds can be manufactured in custom colors in order to meet specific requirements. This task requires blending multiple RoHS-compliant pigments in precise proportions to ensure no color variation and uniform appearance. These colored adhesives can be formulated to meet industrial certifications such as medical grade, NASA low outgassing, ISO 10993-5 for cytotoxicity, and more. Compliance testing is performed by independent testing laboratories.

Click here to learn more. |

| Xometry launches Autodesk Inventor integration

Xometry, one of the country's largest on-demand manufacturing platforms, has launched an Autodesk Inventor add-in that enables Inventor users to get a quote from Xometry without leaving the Inventor design workspace. The add-in makes it simple for Autodesk Inventor users to turn their designs into prototypes and production products. It gives users easy access to Xometry's industry-leading pricing, design feedback, and lead-time information directly in the Inventor environment. Choose from a wide range of processes, including 3D Printing, Sheet Metal, CNC Machining, and Urethane Casting with over 200 materials. An add-in for SOLIDWORKS is also available.

Learn more. |

| LED headlights installed on San Francisco's historic cable cars

Since 1873, the best lighting the historic San Francisco Municipal Cable Cars had was dim incandescent headlights that did not do anything for illumination. They were merely bright enough to serve as an indicator that a cable car was coming. After over 140 years, that finally changed with their upgrade to LED light bulbs from LEDtronics. Along with the PAR46 LED headlights, A19-style LED light bulbs were also installed inside the passenger cabins. Savings on energy costs and maintenance are major benefits.

Learn more. |

| New planetary BLDC gearmotors: High torque and compact design

Bodine Electric Company introduces the new type 22B4-60P planetary gearmotor. This integral gearmotor combines Bodine's high-performance type 22B brushless DC motor with the new 60P (60-mm) planetary gearhead. It is ideal for applications that require higher torque than conventional helical/spur gearheads of a similar size can provide, and where a very low backlash gearhead is not required. Typical applications include conveyors, pumps, packaging, industrial automation, and a wide range of solar- or battery-powered equipment.

Learn more. |

| | Most popular last issue |

| Million-dollar Nissan GT-R50 prototype comes to life

In the space of only one year, Nissan and vehicle design house Italdesign have dreamed up a prototype and made the 50th anniversary GT-R50 concept come to life -- and they've done it with a Midas touch. The gold-accented, 710-hp heavily modified Nissan GT-R NISMO made its debut at the UK's Goodwood Festival of Speed in July, with rumors swirling that it could be destined for a real-world limited production run.

Read the full article. |

| FCA creates new aluminum alloy for engines

A cooperative research effort between Fiat Chrysler Automobiles (FCA), Oak Ridge National Lab, and casting supplier Nemak has created a new aluminum alloy that stays strong up to 300 C (572 F). The new alloy can also be cast and machined using existing technologies. In one application, it may overcome the strength and thermal limits of the aluminum alloys used today for cylinder heads.

Read the full article. |

|

| | Videos+: Technologies and inspiration in action | Honey, I shrunk the V-8 engine!

Borrowing from the classic design of a V-8 engine to achieve high push/pull and holding forces, patented piezo actuator technology and linear stepping motion design principles come together to create the fastest and strongest non-magnetic drive of its class size. These piezoelectric motors are self-clamping -- at rest or in steady-state mode, they automatically hold the position without any need for power. Learn how this technology can be used in your application.

Watch video. |

|

The Rube Goldberg machine: A little history

Rube Goldberg drew thousands of cartoons of his crazy contraptions, but no one actually built one until Purdue University engineering students started a contest in the 1950s. Fast forward to the 21st century, and the official Rube Goldberg Machine Contest is now a global enterprise, with teams of all ages and stripes.

View the video. |

|

|

|