| September 18, 2018 | Volume 14 Issue 35 |

|

| The World's First -- and Best -- Linear Motion Guides

THK's original technology is behind the smooth and silent movement of the "Linear Motion System." The LM Guide is our major product that put the rolling of the linear motion part into practical use for the first time in the world. This improves the accuracy, rigidity, energy saving, velocity, productivity, and service life of the machine. THK offers a full support system from the beginning design phase throughout the maintenance, and follow-up service.

Click here to learn more. |

| | Feature articles | NASA targets three ideas to help transform aviation

NASA's Convergent Aeronautics Solutions project has chosen three new ideas to pursue: a new assembly technique for aero composites, finding ways to reduce and shed heat generated by an electric motor, and exploring use of a water-based solution for generating electricity to replace lithium-based batteries.

NASA's Convergent Aeronautics Solutions project has chosen three new ideas to pursue: a new assembly technique for aero composites, finding ways to reduce and shed heat generated by an electric motor, and exploring use of a water-based solution for generating electricity to replace lithium-based batteries.

Read the full article. |

|

|

|

| Air Operated Conveyors

EXAIR's Line Vac connects to standard hose or tube to create a powerful conveyor. The design features large throat diameters for maximum throughput capability. A small amount of compressed air is injected through directed nozzles to produce a vacuum on one end and high output flows on the other.

Web site offers detailed information. |

| Motors for model train meet demanding requirements

Building an N-gauge (1:160) model train system involves working with very small units. The 1930s-inspired BR 70 locomotive from Fleischmann is only 2.25 in. long when measured buffer to buffer. As on large locomotives, traction (and on the model, power transmission) between the wheel and the track is a crucial factor. To give the unit appropriately scaled big-train power with low vibration and noise, the folks at Fleischmann turned to customized DC motors from the FAULHABER Group.

Read the full article. |

| Top Technical Tips: Interlaced wave springs

When heavy loads are necessary with a demand for greater travel, Smalley Interlaced Wave Springs can handle weighty loads in small places. Interlaced wave springs can replace heavy-duty coil springs or Belleville stacks. An interlaced wave spring is formed from two constituent wave springs of similar thickness, amplitude, and frequency. The two individual wave springs are combined together by interlacing them so that the spring turns of each spring abut each other for the entire length of the interlaced spring.

Learn more. |

| DuPont announces newest in-mold electronics inks

DuPont Electronics and Imaging is launching its second generation of In-Mold Electronic (IME) materials with key advancements in its electrically conductive adhesive, protection encapsulant, and crossover dielectric. IME technology enables functions such as touch controls and lighting to be directly embedded inside plastic parts by printing circuits onto plastic sheets, which are then thermoformed and injection molded. This allows product engineers to reduce weight and cost while increasing design aesthetics and functionality in everything from car dashboards to home appliances, using fewer parts and manufacturing steps.

Learn more about the latest materials.

Go to the DuPont In-Mold Electronic Technology website. |

| First explosion-proof stackable multi-turn encoder

Sensata Technologies has introduced the first explosion-proof stackable multi-turn encoder, an ideal position sensing solution for oil and gas applications such as drawworks, top drives, and pipe-handling equipment where working conditions are extreme. The new encoder, BEI Sensors' model MAAX, is ATEX and IECEx certified to operate in explosive environments and features a Profibus output in a unique, stackable package. CANopen and SSI outputs are also available. The MAAX provides up to 16 bits of resolution as well as up to 16 bits of turns by mechanical counting. This workhorse product operates directly in Zone 1 environments without the need for an accompanying Intrinsic Safety barrier.

Learn more. |

| Test your knowledge: High-temp adhesives

Put your knowledge to the test by trying to answer these key questions on how to choose the right high temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Take the quiz. |

| Spinning flare nuts eliminate loose fasteners in thin metal sheet applications

PEM SFN spinning flare nuts from PennEngineering become permanently captivated upon installation in thin metal sheets and, when paired with a self-clinching stud or other fixed externally threaded hardware, can eliminate all loose fasteners (including flange nuts) in attachment applications. These one-piece, flanged hex nuts additionally will spin freely in a sheet enabling quick attachment to mating hardware. Their use ultimately promotes savings in assembly time and costs.

Learn more. |

| Compact electronic slide bolt

Southco has expanded its line of electronic access control solutions with a compact electronic slide bolt that simplifies the upgrade from mechanical to electromechanical latching. The lightweight EM-05 5 Series Electronic Slide Bolt is suitable for light-load applications where space is limited, and the efficient gear motor-driven mechanism can be easily integrated with any control system. This unit features simple push-to-close functionality and offers an upgrade in energy efficiency compared with solenoid solutions, as no power is required to maintain the product's retracted or extended position. It offers simple installation and retrofits.

Click here to learn more. |

| | Videos+: Technologies and inspiration in action | Will it melt? 3D-printing heat-resistance test

How much heat will different 3D-printed materials withstand? Xometry's Director of Project Engineering, Greg Paulsen, tests the heat resistance of 3D-printed parts made with Veroclear, ASA, Nylon, Polycarbonate, Ultem 9085, Ultem 1010, and PPSF. Watch the company's latest challenge and find out how each material measures up!

View the video. |

|

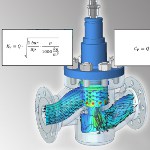

Understanding pressure losses using CFD

Early pressure drop investigations and optimizations are crucial for today's efficient designs. This short 3-minute video from Mentor shows you how to conduct pressure drop characterizations such as determination of kv or cv coefficients in FloEFD, the leading frontloading CFD simulation solution for design engineers.

View the video. |

|

|

|