| September 25, 2018 | Volume 14 Issue 36 |

|

| Metal Bellows for Sensors and Instrumentation

Servometer ® miniature bellows can be added to instrumentation and manifolds of almost any shape or size. Barometric and differential pressure, gauge, and temperature can all be compensated for using bellows technology. Electrodeposited bellows have been used to increase the accuracy inside capacitive and potentiometric pressure sensors to increase linearity. You can request a free sample too (top right of website).

Learn more. |

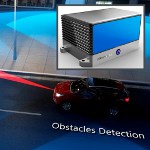

| Low-cost LiDAR comes to mass vehicle production

Chinese manufacturer RoboSense says that its new, high-performance solid-state LiDAR system for autonomous driving is 1/400th the price of traditional 64-line LiDAR systems and has updated features not found in even higher priced systems. The $200 RS-IPLS Intelligent Perception LiDAR system (yup, the price really is two Benjamins) is designed for the mass production of vehicles. On price, that's a huge fall from the first under-$10,000 systems rolled out in just the last two years.

Read the full article. |

| 'Wearable cockpit' concept for pilots becoming a reality

BAE Systems is working on a novel way for pilots to fly fighter jets. Researchers and engineers at the U.K.-based military and defense company are developing technologies to enable pilots to control the fighter jet of the future with the blink of an eye, creating a software-only cockpit that's upgradable, adaptable, and reconfigurable -- and it's planned for 2025.

Read the full article. |

| Get your CAD under control before implementing PLM

Despite the widespread adoption of PDM and PLM technology by large companies, the vast majority of companies below 20 designers have yet to implement these solutions and still just use shared drives to store their CAD files. Each year that passes without PDM/PLM is another year of CAD data becoming more disorganized, which makes it even more difficult to migrate to a new system. But some companies are turning to CAD geometry indexing and search technologies to better aggregate their existing CAD file shares. By Jon Gable, Adaptive Corporation

Read the full article. |

| Conserve precious liquids with patented no-drip atomizing nozzles

EXAIR's new 1/8 NPT No Drip External Mix Atomizing Spray Nozzles mix liquid and air outside the nozzle and allow the air and liquid flows to be adjusted independently. The new, patented No Drip External Mix Atomizing Spray Nozzles work in the same way the company's standard atomizing nozzles do, but have the added benefit of positively stopping liquid flow when compressed air is shut off. Post-spray drips waste precious resources such as expensive coatings, chemicals, or water.

Learn more. |

| Modern CAD for Machine Design (new eBook)

In Onshape's latest eBook, "Modern CAD For Machine Design," you'll be introduced to five machinery companies that recently modernized their entire design and manufacturing process with one key decision: switching to a modern, cloud-based CAD system, enabling their design teams to cast aside old software headaches and focus on doing their best work. You'll read insights from: GKS Packaging (Vertical Form, Fill and Seal Machines), Universal Logic (Artificial Intelligence/Robotics), Voxel Innovations (Pulsed Electrochemical Machining), Hirebotics (Robotics), and Absolute Machinery (Injection Molding).

Get your eBook today. |

| Traction drives leverage engineered fluids

Rolling Motion Industries (RMI) has released two high-efficiency traction drives: the MAR-17-1-2.1 (speeds to 3,600 rpm with 10 to 20 in./lb of torque) and MAR-23-1-2.1 (3,600 rpm with 20 to 30 in./lb of torque). These one-way traction drives have only six moving parts and use an engineered traction fluid with a coefficient of friction of just 0.1 to 0.12. These traction drives typically last three times longer than conventional gearboxes, and with no metal-to-metal contact they generate up to 72 percent less heat after 24 hr of continuous operation. Additionally, they create up to 38 percent lower dB at 3,000 rpm than conventional gearboxes (less than a home refrigerator). Applications include: pumps, blowers, fans, turbo and superchargers, conveyers, HVAC systems, and medical -- anything that rotates.

Learn more. |

| Industry's first 100-W and 200-W USB Type-C controllers

Texas Instruments has introduced two new USB Type-C and USB Power Delivery (PD) controllers, with fully integrated power paths to simplify designs, minimize solution size, and speed time to market. The TPS65987D and TPS65988 offer system designers the industry's highest level of integration to reduce design complexity and overall cost. The devices are the industry's first USB PD controllers to source 100 W and 200 W of power, respectively, to support computing applications and enable the benefits of USB Type-C in additional applications such as cordless power tools, gaming, and virtual reality headsets.

Learn more. |

| | Videos+: Technologies and inspiration in action | How to measure the free height of a Smalley crest-to-crest wave spring

Engineers often ask Smalley engineers, "How do I measure the free height of a wave spring?" Knowing how to properly measure a wave spring at its free height can save valuable inspection time. It is also important to know that the free height of a wave spring is typically a reference dimension, because Wave Springs are ordinarily designed to provide a specific load at a work height. The work height is the dimension we tolerance on, Smalley says.

Engineers often ask Smalley engineers, "How do I measure the free height of a wave spring?" Knowing how to properly measure a wave spring at its free height can save valuable inspection time. It is also important to know that the free height of a wave spring is typically a reference dimension, because Wave Springs are ordinarily designed to provide a specific load at a work height. The work height is the dimension we tolerance on, Smalley says.

Learn how to measure free height. |

What is Electron Beam Additive Manufacturing? 19-ft-long parts!

Sciaky launched its groundbreaking Electron Beam Additive Manufacturing technology in 2009 with the objective to save manufacturers time and money on the production of large-scale, high-value metal parts and prototypes. Today, Sciaky's EBAM technology remains the largest, fully programmable means of achieving near-net-shape parts made of weldable metals that are available in wire feedstock. These materials include: Titanium and Titanium alloys; Inconel 718, 625; Tantalum; Tungsten; Niobium; Stainless Steels (300 series); 2319, 4043 Aluminum; 4340 Steel; Zircalloy; 70-30 Copper Nickel; and 70-30 Nickel Copper. Make metal parts up to 19 ft x 4 ft x 4 ft!

Sciaky launched its groundbreaking Electron Beam Additive Manufacturing technology in 2009 with the objective to save manufacturers time and money on the production of large-scale, high-value metal parts and prototypes. Today, Sciaky's EBAM technology remains the largest, fully programmable means of achieving near-net-shape parts made of weldable metals that are available in wire feedstock. These materials include: Titanium and Titanium alloys; Inconel 718, 625; Tantalum; Tungsten; Niobium; Stainless Steels (300 series); 2319, 4043 Aluminum; 4340 Steel; Zircalloy; 70-30 Copper Nickel; and 70-30 Nickel Copper. Make metal parts up to 19 ft x 4 ft x 4 ft!

Learn all about it. |

|

|