| November 13, 2018 | Volume 14 Issue 42 |

|

| Precision Motion Stages for Machine Builders

Design engineers in the precision automation market often put different things at the top of their requirement lists than their colleagues in the instrumentation sector. Some requirements could include robustness, minimum dimensions, dynamic performance, and 24/7 reliability. The latest stage designs provide a number of advantages that deserve a closer look.

See it in action> |

| Guide to overmolding best practices

Overmolding is a great injection molded feature you can utilize in your design to capture color contrasts, add flexibility or eliminate assembly. Take advantage of this feature by learning how to design your part for overmolding.

You'll learn:

- How to set up your design for complex overmolding

- Material evaluation and best practices for proper adhesion

- Feature specifications to consider for good overmolds

Get the Xcentric overmolding guide (no registration required). |

| | Feature articles | NASA investigates ultrafast laser machining

An ultrafast laser that fires pulses of light just 100-millionths of a nanosecond in duration could potentially revolutionize the way that NASA technicians manufacture and ultimately assemble instrument components made of dissimilar materials. They could even eliminate epoxies.

Read the full article. |

|

|

|

| 100 years ago: Final Allied offensive of WWI decided fate of Europe

By mid-September 1918, the French and U.S. armies under the command of Gen. John J. Pershing had achieved victory in a critical campaign, driving back the Germans from the Saint-Mihiel salient. With that area secured, about 600,000 Americans, along with some 220,000 French and Italian troops, moved 40 miles to the northwest along the bank of the Meuse River in the Meuse-Argonne region of France.

Read the full article. |

| Wheels: New Chevy Silverado with advanced 2.7L Turbo rivals some V6 models

More torque, higher horsepower, and better city mpg. What truck owner wouldn't want that? The all-new 2019 Chevrolet Silverado 1500 with 2.7L Turbo offers full-size truck customers 14 percent more torque and 13 percent better city fuel economy than the 4.3L V6 it replaces (plus it's more than a full second quicker from 0 to 60 mph). This four-cylinder turbo is a first for Chevy -- and for any full-size pickup.

Read the full article. |

| Engineer's Toolbox: How to maximize retention of spring pins

Spring pins are used in many different assemblies for a variety of reasons: to serve as hinge pins and axles, to align components, or simply to fasten multiple components together. When properly implemented, they provide reliable, robust joints with excellent retention. SPIROL Application Engineer Evan Dowell runs through the dos and don'ts of using spring pins.

Read the full article. |

| 'It's like Uber for manufacturing': Meet Xometry

Manufacturing is a notoriously finicky business. But smaller machine shops dependent on a handful of local customers in a single industry are particularly vulnerable to the whims of economic downturns. Since finding new work can be costly and time-consuming, some have been hoping for an Uber-like service for manufacturing. The Maryland-based company Xometry recently developed that very model. By Amy Kover, GE Reports

Read the full article. |

| Alternative to traditional drive systems

Nexen Group has introduced a stainless steel version of its patented precision roller pinion system (RPS). The Nexen RPS engages two teeth simultaneously to achieve superior accuracy with zero backlash at any length. The system is also extremely quiet and 99 percent efficient. Stainless steel makes the system corrosion resistant, with a long life of up to 36 million meters. Nexen's RPS provides a low-maintenance, durable alternative to rack and pinion, ball screw, and belt drive technology. The RPS is used for a wide range of applications including laser cutting, plasma cutting, and gantry applications.

Learn more. |

| Cool Tools: Desktop full-color 3D printer

The all-new XRIZE desktop industrial 3D printer enables users to manufacture functional polymer and composite parts in full color. And since RIZE's intelligent and innovative solutions focus on the user as much as the machine, XRIZE is easy to use, safe, and enables markup to provide much-desired IP security, traceability, and branding. This machine requires minimal pre-processing, post-processing, and material management. It uses a patented Augmented Deposition process by extruding an engineering-grade thermoplastic and simultaneously jetting C-M-Y-K inks through industrial printheads to achieve the full-color part. Build volume is 12 x 8 x 8 in. (310 x 200 x 200 mm). New carbon fiber materials also available.

Learn more. |

| High-precision multi-axis motion with hexapod 6-axis systems -- New 130-pg PI catalog

Multi-axis motion and positioning systems are often used for precision automation and alignment applications in fields including optics, photonics, aerospace, medical engineering, and laser technology. Hexapod parallel-kinematic motion and positioning systems provide a novel approach to multi-axis motion, combining precision and compactness with versatility. PI's new 130-page catalog provides background information and features a variety of hexapod (Stewart-Platform) motion and positioning systems with 6 degrees of freedom and high resolution and repeatability in the sub-micrometer and even nanometer range.

Get the new catalog today (no registration required). |

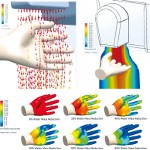

| Modeling challenge: Fastest way to dry your hands? FloEFD investigates

Have you ever wondered what's the fastest way to dry your hands when using one of those air-shooting hand dryers in a public restroom? Should you rotate your hands or leave them in one place? Proving that modeling everyday challenges is fun and insightful, Robin Bornoff from Mentor tackles these questions using the full-featured 3D fluid flow and heat transfer analysis simulation tool called FloEFD.

Read the full article. |

| Know your materials: Nylon 12CF

FDM Nylon 12CF is a chopped carbon fiber-filled polyamide 12 material that is available for 3D printing on compatible Stratasys Fortus production systems. The material is 35 percent carbon fiber by weight and has a high strength-to-weight ratio with a tensile strength on par with high-performance FDM material. The 3D design and rapid prototyping specialists at TriMech run through what you need to know about this exciting and versatile material.

Read the TriMech blog. |

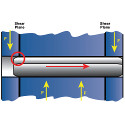

| Two-way traction drives reduce motor torque ripple

Rolling Motion Industries (RMI) has released two new, highly efficient two-way gearless traction drives. The MAR-17-2-2.1 and MAR-23-2-2.1 permanently lubricated drives have only six moving parts and typically last three times longer than conventional gearboxes. The drives have demonstrated up to an 84 percent reduction in motor torque ripple. The MAR17-2-2.1 Traction Drive is designed for speeds to 3,600 rpm with 10 to 20 in./lb of torque, and the MAR-23-2-2.1 Traction Drive is rated for 3,600 rpm with 20 to 30 in./lb of torque.

Learn more. |

| | Most popular last issue |

| Mopar reimagines 1968 Dodge Charger with 1,000-hp 'Super Charger' concept

Dodge and Mopar set out to wow the crowds at the 2018 Specialty Equipment Market Association (SEMA) Show Oct. 30 to Nov. 2 -- and boy did they ever with the 1968 Dodge "Super Charger" Concept. The stealthy muscle car, excitingly faithful to the original design language, features modern elements from the current Dodge Charger SRT and Challenger SRT lineup to showcase the new 1,000-hp "Hellephant" 426 Supercharged Mopar Crate HEMI V8 engine and kit.

Read the full article. |

| Inside look: Painting cars for Mars

NASA's JPL paint shop does a thousand different paint jobs a year. And while every piece of spacecraft that comes through the shop is important, one headed for the Red Planet -- in this case, the Mars 2020 rover -- adds a little extra oomph.

Read the full article. |

|

| | Videos+: Technologies and inspiration in action | |

|

|