| May 21, 2019 | Volume 15 Issue 19 |

| PEEK High-performance Engineering Thermoplastic for Industrial Applications

Polyetheretherketone (PEEK) is valued for its excellent performance in the automotive, electronics, aerospace, energy, and manufacturing industries. It has excellent mechanical properties and chemical resistance across a broad temperature range, and exhibits extremely high resistance to steam sterilization, excellent radiation resistance, and low outgassing under vacuum. It is available as film, sheet, fiber, monofilament, powder, granule, tube, rod, mesh, and fasteners.

For specifications and pricing, click here

or email

info@goodfellowusa.com. |

| 50 Years Ago:

Apollo 10 aims to sort out the unknowns -- Part 1

As Commander Thomas P. Stafford stated during a preflight press conference in April 1969, Apollo 10 was planned to "sort out all the unknowns" to make the Moon landing possible. That press conference was held about a month before the critical mission, which was a dress rehearsal for the lunar landing mission -- a goal President John F. Kennedy set for the nation eight years earlier. [Countdown Series: 50th anniversary of Apollo 11]

Read the full article. |

| New Mercedes crossover concept gets sporty

The crossover SUV market is so hot, that just about every major car manufacturer has one. Mercedes has a couple already in the coupe-like GLA and GLC, so making a GLB concept model that is a little more beefy fits right in. What differentiates this one is its sporty appearance, complete with designer touches. In 2018, SUVs were the strongest segment for Mercedes-Benz, so riding the trend gives Daimler a lot of design room to play.

Read the full article. |

| Mike Likes: Small diameter retaining rings and wave springs from Smalley

From medical devices to electronics, the world around us is getting smaller. "How small can you go?" This is a question a Smalley engineer hears all the time ... but a better question is how small do you need? As The Engineer's Choice™ for Wave Springs and Spirolox® Retaining Rings, Smalley has the answer! Smalley's manufacturing capabilities now allow them to design and manufacture Wave Springs and Retaining Rings down to 0.165", 4 mm diameters!

Learn more. |

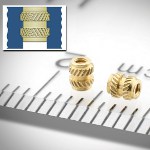

| Designing with threaded metal inserts for plastics

When deciding how best to attach plastic materials or components in an assembly, designers can choose several options, including adhesives or rivets. But what if disassembly and reassembly will be necessary for the unit down the road? The practical solution: threaded metal inserts. Bob Gallagher from PennEngineering runs through your insert fastening options, processes, materials, and sizes.

Read the full article. |

| Precision dispensing for micro-electronics

The spread of miniaturization in automation has led to an ever-increasing demand for optimum dispensing of the tiniest volumes. Whether in electronics or micro-mechanical engineering, solder pastes, adhesives, lubricants, and 3D-printing filament must be applied or extruded precisely where needed, in exactly the right dosage and without spillage or dripping. Compact, high-torque DC motors deliver the precision and small size needed for such a challenge.

Read the full article. |

| Optimize mechanical misalignments, get hidden benefits

C-Flex Couplings combine the best qualities of disc, beam, and bellows couplings in a unique and economical new design. Made to couple two rotating shafts together, these couplings can accommodate large misalignments while transmitting high-torque loads with zero backlash. Benefits include lower energy usage and less-frequent bearing failure, since less stress is placed upon bearings. Constructed using high-strength hardened stainless steel or glass impregnated polyamide flexures, these couplings require no maintenance and provide years of trouble-free life, even in contaminated environments. Flexible Pivot Bearings and Super Plastic Torsional Damping Couplings also available.

Click here to learn more.

Watch C-Flex Couplings in action handling misalignments. |

| Why convert hydraulics to electric high-force linear actuators?

Got a high-force linear motion application? If you do, chances are the first product solution to come to mind is hydraulic cylinders. They're relatively inexpensive (if you already have a hydraulic power unit in place), compact (if the HPU is somewhere else), and power-dense. But what about the disadvantages -- leaks, operation and maintenance costs, and more? It's possible to convert an application from hydraulic to electric linear motion easily, and Tolomatic even gives you step-by-step instructions.

Read the Tolomatic blog. Really useful! |

| Metal injection molding limits secondary operations

Smith Metal Products specializes in metal injection molding (MIM) of soft metal alloys and an array of other metals for small electronic and electrical components. Ideal for the fast-changing needs of the telecom and electronic markets, MIM uses the latest tech built around an automated production process. Parts begin when metal powder is suspended in a binder or feed stock that is then injection molded into a tool. Then the part goes through a debinding and sintering process to form a full, dense metal part. The resulting parts are very precise, net-shaped, and can be produced faster than machining -- and usually with no secondary operations. Parts most suitable include those made from a full range of alloy materials, including soft metal, stainless steels, and Titanium.

Learn more. |

| 25% more speed: Proven high-speed machining unit gets even faster

Specifically for metals with high cutting speed rates or small-diameter hole-drilling applications, the SUHNER SPINDLEmaster has been proven in thousands of installations. Now the BEX15 unit provides new speed options -- reliably up to the maximum speed limit. With an increase of 25 percent up to a permissible maximum spindle speed of 23,000 rpm, operations requiring higher spindle speeds can be accomplished more easily. This improvement is the result of a complete redesign of drive and spindle bearing components.

Learn more. |

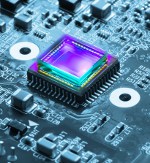

| Cool heat-sensitive CMOS sensors with thermoelectric modules

Laird Thermal Systems has expanded its Peltier thermoelectric module product family with the HiTemp ET Series, designed to protect critical electronic devices like CMOS sensors in high-temp applications. Recent advances in CMOS sensor tech have made these sensors practical and effective for use in a wide range of imaging applications found in autonomous systems, machine vision and learning, high-end scientific cameras, and more. HiTemp ET Series thermoelectric modules deliver spot cooling capacity of more than 300 W to ensure optimum CMOS sensor performance. Fifty-three models offer a variety of heat-pumping capacities, geometric form factors, and input voltages.

Learn more. |

| | Most popular last issue |

| One-armin' the '52 Fetzenflieger with Porsche factory racing engine

There have been a lot of racing legends throughout the history of motor sport, but none can quite compare to Austrian driver (and mechanical engineer) Otto Mathé, who, despite having only one functional arm, not only drove to victory in each of the 20 races he entered in 1952, but also built his own cars exclusively featuring Porsche engines. In the mid-1950s, he became well known for building, driving, and winning in an unusual, sometimes fiery vehicle dubbed the "Fetzenflieger."

Read the full article. |

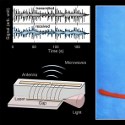

| Researchers build first laser radio transmitter

Researchers from the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) demonstrated a laser that can emit microwaves wirelessly, modulate them, and receive external radio frequency signals. The research opens the door to new types of hybrid electronic-photonic devices.

Read the full article. |

| Ford to develop EV based on Rivian's flexible skateboard platform

Do you remember that super-cool Rivian all-electric pickup we featured in Designfax last December? Ford Motor Co. has made a $500 million equity investment in Rivian, and the two companies have agreed to work together to develop an all-new, next-generation battery electric vehicle for Ford's growing EV portfolio using Rivian's skateboard platform.

Read the full article. |

|

| | Videos+: Technologies and inspiration in action |

Rolls-Royce pushes ceramic matrix composite development

Learn how Rolls-Royce is pushing ceramic matrix composite (CMC) material development and processes to the next level for use in next-gen aircraft engine components at their facility in Cypress, CA, and around the world. The company says, "CMCs deliver the high-temperature capability of ceramics with the strength and reliability that is required for gas turbine engine applications, but weigh less than current alloys" and "help save on fuel consumption, since they are lighter weight and require less cooling over traditional nickel-based components." CMC components are already being used for aerospace test programs including Advance3, which demonstrates the new core design for the UltraFan engine.

Watch the video. Really interesting! |

|

|

|