| November 26, 2019 | Volume 15 Issue 45 |

|

| eBook -- How to Select the Right Manufacturing Solution

From rapid and functional prototyping, appearance models to low-volume production using both additive manufacturing and traditional subtractive processes; the choices to develop your project are almost endless. Download the 3D Systems eBook to learn from our team's expertise and knowledge combined with advanced materials and 3D Systems printing technology.

DesignFax readers get free shipping on all SLS and SLA part orders until December 30th 2019.

Get the eBook and Discount Code Today. |

| Best-kept secret in the circuit breaker industry

When STELPRO, a Quebec-based manufacturer of integrated heating solutions for the HVAC industry, asked partners all along its supply chain to identify cost-saving opportunities, installing NOARK miniature circuit breakers in panels on all their equipment was one solution that provided long-term quality and savings (typically 30 to 50 percent in price). NOARK's five-year warranty was a huge added bonus.

Read the full article. |

| | Feature articles | Diesel gets way cleaner with new injector technology

An engine innovation first conceived and tested by Sandia National Lab has attracted the attention of big business because of its potential to eliminate between 50 to 100 percent of diesel soot emissions and maintain or improve engine performance. The idea for ducted fuel injection came from studying a simple Bunsen burner.

An engine innovation first conceived and tested by Sandia National Lab has attracted the attention of big business because of its potential to eliminate between 50 to 100 percent of diesel soot emissions and maintain or improve engine performance. The idea for ducted fuel injection came from studying a simple Bunsen burner.

Read the full article. |

|

|

|

| U.S.-based Shape Corp. wins Swedish Steel Prize 2019

Shape Corp. of Grand Haven, MI, a full-service supplier of lightweight steel, aluminum, and plastic solutions primarily for the automotive sector, was named the winner of SSAB's 20th international Swedish Steel Prize in Stockholm, Sweden, on Nov. 14. Shape won for its groundbreaking use of martensitic steel in a 3D-formed tube for automotive roof rail applications. Other finalists included a metal solar roof maker, a soybean-harvesting machine maker, and a fabricator of mining excavator equipment.

Read the full article. |

| Trends in fastening technology: Smaller, lighter, easier to install

Fastening technologies and assembly techniques are evolving to meet continued demands for reliability, throughput, and ease of manufacturability. One trend sees designers involving parts manufacturers in early design phases to ensure design for manufacturability (DFM). Another sees the fasteners themselves becoming smaller, stronger, lighter, and easier to install by automated and robotic assembly systems. Traditional and robot-ready fastener machines are also evolving. By Michael Wolff and Ron Boggs, PennEngineering

Read the full article. |

| Flexible Circuit Design Guide

Tech-Etch uses advanced techniques to manufacture flex and rigid-flex circuits to exacting customer specifications. Special processes include selective plating a single circuit with two different finishes, contoured circuits with variable metal thickness, semi-additive and subtractive techniques, open window or cantilevered contact leads, plus SMT for component assembly. Tech-Etch specializes in flexible circuits for medical device, medical implant, telecommunications, aerospace, semiconductor, and other high-reliability electronic applications.

Get your guide today (no registration required). |

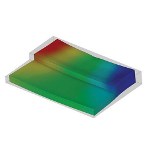

| How to calculate plastic injection molding shrinkage

Do you know how to calculate the shrinkage of your part ahead of time? Plastic injection molding shrinkage is the contraction of a plastic molded part as it cools after injection. Most of the part shrinkage occurs in the mold while cooling, but a small amount of shrinkage occurs after ejection, as the part continues to cool (especially for Delrin or POM). After that, the part may continue to shrink very slightly for several hours or even days until the temperature and moisture contents stabilize.

Read the ICOMold blog. |

| New ball screw for machine tools

Featuring high-speed performance and load capacities that exceed existing full ball standards, THK's new Type BSM Ball Screw is ideal for use in machine tools. The Type BSM uses a newly developed circulation structure and a large lead to meet high-speed performance demands. The DN value is 170,000, contrasted with 130,000 in conventional products. The unique groove design and double groove structure improve load capacity. The Slim Nut Type BSM-B conserves space with a nut diameter up to 14 percent more compact than THK conventional ball screws. An extended overall length and increased number of loaded circuits ensure optimum rigidity.

Learn more. |

| New hygienic integrated electric actuators provide modular clean-in-place solutions

The Tolomatic IMA-S stainless-steel integrated servo actuator is designed for the most demanding food and beverage processing applications, eliminating harborage points and preventing bacterial growth. The 316 stainless-steel construction provides excellent corrosion resistance and withstands high pressure, high temperature, and caustic washdown. It meets clean-in-place requirements, allowing machine designers to achieve open machine designs and eliminate shrouding required to house standard actuators. This series offers forces up to 11.1 kN (2,500 lbf), stroke lengths up to 450 mm (18 in.), and options for planetary roller screws or ball screws. A proprietary lubrication feature helps extend service life.

Learn more. |

| A proportional isolation valve like no other

Clippard's new patented ceramic technology is the first to provide precise proportional control combined with isolation valve attributes to meet the needs of the most stringent analytical and industrial process control applications. This valve is ideal in critical applications for liquid and gas delivery, medical, analytical, and industrial automation requiring ultra-fine resolution and excellent repeatability. In addition, the unique design allows for custom flow profiles.

Learn more. |

| Need help coupling two parallel shafts?

Electromate offers a full family of power-on clutches from Inertia Dynamics for most applications. Power-on clutches are used to couple two parallel shafts. The armature hub assembly is mounted to the same shaft as the rotor assembly. The armature hub accommodates a pulley, gear, sprocket, etc., to transmit torque to the second shaft. The field assembly is mounted on the shaft and retained by a loose-fitting pin or bracket through the anti-rotation tab. Typical applications include: packaging machinery, medical equipment, conveyors, postal sorters/readers, document feeders, textile equipment, and copiers/printers.

Learn more. |

| | Most popular last issue |

| Ford unveils all-electric Mustang Mach-E SUV

Ford Motor Co. took the wraps off its latest Mustang Sunday night, and it was full of surprises. First, it's an SUV called the Mach-E. Second, it's all electric. Yup, the pony car now has a family-friendly, zero-emissions alternative available in late 2020. Buyers will have a host of options, including a 459-hp GT Performance Edition with an extended range of 300 miles that does 0 to 60 in around 3.5 sec. And you get a kit to charge it at home.

Read the full article. |

| Navy demonstrates laser power beaming

Attendees recently gathered at the Naval Surface Warfare Center to stand around in the dark and look at something they mostly couldn't see. It was a long-range, free-space laser system -- the first of its kind -- beaming 400 W of power across 325 m to specially designed photovoltaics.

Read the full article. |

|

| | Videos+: Technologies and inspiration in action | New Spirawave® Wave Spring Series

Smalley's Nested Spirawave Wave Springs are now available as standards. These flat wire springs are coiled in parallel with multiple turns to produce high loads, and are ideal for applications requiring high forces in tight spaces. When replacing single-turn wave spring stacks with one nested spring, misalignment and uneven loading are eliminated, simplifying assembly. Standard or custom, Smalley will provide you the right part, in the right material, with No Tooling Charges™.

View the video. |

|

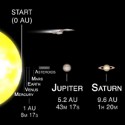

What warp speed actually looks like

Ever wondered what it would look like to see a spaceship traveling at warp speed across our solar system? Well you're in luck, because Dr. James O'Donoghue (a planetary scientist at the Japanese space agency JAXA and former NASA Fellow) has put together an animation to do just that. Get your Star Trek on as you follow a spacecraft in real time racing increasingly faster from the Sun to Pluto. From the far left, even moving at Warp 2 (10X speed of light) looks surprisingly slow -- but then again, it's a long way to go.

View the video. |

|

|

|