Mechanical News

New carbon black alternative is made from scrap tires

Carbolytic Materials Company (CMC) of Maryville, MO, has developed a carbon black alternative with the trade name ApexCM that provides significant cost-reduction opportunities for many manufacturers who use carbon black to reinforce rubber products and tint plastic materials. Reclaimed from scrap tires, ApexCM is an affordable and environmentally sound option, according to its maker. Up to 40% of scrap tires generated annually could be successfully processed, saving critical landfill space.

"Our ability to provide a cost-effective alternative to carbon black for both tinting and reinforcing makes our product very appealing to manufacturers," says Ray Riek, CEO of CMC. "Although ApexCM does not substitute for carbon black in every application, the independent laboratory results have impressed many engineers with the versatility, functionality, and the overall value proposition."

ApexCM is a lower cost alternative to carbon black extracted from scrap tires. Carbolytic Materials Company uses cost-effective, proprietary technology to manufacture this revolutionary powder or pellet carbon. ApexCM can directly replace N700 and N900 carbon blacks for reinforcing and tinting rubber and plastics. It can also replace N500 and N600 carbon blacks in certain applications. With rising petroleum prices and enhanced focus on environmental savings, the value of reclaimed carbon black goes beyond the bottom line.

Recently the company has secured funding to build a new manufacturing facility in Maryville that is expected to produce between five and ten thousand tons of material annually.

Want more information? Click below.

Carbolytic Materials Company

Mechanical Products

A totally new technology for fastening sheet metal panels

The 1-035SL Captive-Joiner 9.5 SNAP-LINE offers all the benefits of traditional captive screws plus improved ease-of-use by the end-user, significant reduction in time of installation, and reduction in the risk of damage to sensitive electronic equipment housed inside enclosures. The Captive-Joiner also functions as a slam-to-close latch, requiring just a simple push of the panel against the frame to ensure latching.

The Captive-Joiner incorporates D•SNAP Technology making it quick and easy to install into the panel — reducing installation time up to 90% and giving significant cost savings. SNAP-LINE Captive-Joiners do not require mounting hardware (screw, nuts, or bolts) or tools for installation and can be used in blind applications when access to the back of the panel is restricted. They are ideal for applications under extreme vibration conditions because they will not loosen from the panel.

Want more information? Click below.

Dirak

Gore improves thermal performance of its Direct Air Cooling Filter

The new GORE Cooling Filters improve thermal cooling while reducing both capital and operating costs in wireless base stations, MCPAs, base band units, power cabinets, switching systems, and other outdoor electronic enclosures.

The benefits of using the new GORE Cooling Filter are twofold: improved cooling efficiency and reduced costs. The filter improves thermal cooling approximately 20% by allowing higher airflow through the filter. At the same time, the membrane protects the electronic components by preventing fine contaminants such as dirt, dust, and sand from entering the enclosure. By increasing airflow while reducing potential contaminant damage, the GORE Cooling Filter improves overall reliability of telecommunications infrastructure.

Want more information? Click below.

Gore

Water-soluble oil specifically designed for aluminum

Rustlick Ultracut AL is a high-performance water-soluble oil specifically formulated for aluminum to prevent staining during the machining process. It can be used with all metals, including ferrous, non-ferrous, brass, bronze, and copper, though it is not recommended for use on magnesium.

The biostability of Rustlick Ultracut AL makes it highly resistant to bacteria and fungus, and with proper maintenance it can significantly prolong sump life. Rustlick Ultracut AL contains non-chlorinated EP additives as well as boundary lubricants and creates a light oil barrier that protects the working part and the machine from rust. Rustlick Ultracut AL is also great for environments with hard water problems since it provides strong emulsion stability. Rustlick Ultracut AL is available in 5- or 55-gal containers. It is a light brown viscous fluid in its concentrated form. It can be diluted 10:1 to 40:1 depending on the application.

Want more information? Click below.

ITW Rocol

Automatic press benefits from turret tool system

The PEMSERTER Series 2000 automatic press accommodates a dual-bowl option and QX Turret Tool system to allow quick and efficient changes between anvil tools while installing different types of self-clinching fasteners. Using the second bowl and the turret tool system, two fastener types can be installed in automatic feed mode and two in manual feed mode for steamlined job productivity and quality.

Touch-screen setup for all four stations includes selection of installation force and number of fasteners to be installed per workpiece. Operators are notified by visual and/or audible signal to rotate the turret to the next location or that the job is completed per setup. The CE-certified press offers a 24-in./61-cm throat depth, performs at cycle rates up to 2,750 strokes/hr, and delivers a ram force of 400 lb to 16,000 lb/2.7 kN to 71.2 kN.

Want more information? Click below.

PennEngineering

Visible light-cure adhesive for medical device assembly

For medical bonding, potting, and sealing applications, Henkel Corporation introduces a rapid curing, highly flexible visible light-cure adhesive formulation, Loctite 3974. Curing tack-free in seconds, this new adhesive permanently bonds materials with differing coefficients of thermal expansion (CTE) and easily accommodates substrate expansion and contraction.

Loctite 3974 Light Cure Adhesive is a low-modulus, single-component acrylic adhesive that cures rapidly on exposure to UV or visible light. This adhesive can be used on glass, thermoplastic, and metal assemblies that must withstand extreme thermal cycling and environmental exposure. Loctite 3974 Light Cure Adhesive has a Shore hardness of A70 and an elongation of 100%, making it ideally suited for highly flexible components.

Want more information? Click below.

Henkel

3-ton freestanding custom crane systems

Konecranes Americas introduces the K-Trac line of freestanding custom cranes. K-Trac custom crane systems provide a cost-effective lifting solution designed to customer specifications with lifting capacities up to 3 tons.

The K-Trac crane system can be customized to accommodate design specifications that include runway and bridge length, post and hook height, and the location of electrical input. In addition, every K-Trac is modular, allowing for easy modification and reconfiguration in the field. The K-Trac maximizes the use of limited work areas. The raised bridge end provides maximum lift in restricted spaces such as low ceilings and elevated obstructions.

Want more information? Click below.

Konecranes

400-hp convertible water jet unit

NLB Corp. has introduced the NLB 325 Series convertible water jet units, which operate at up to 400 hp at any of six pressures up to 24,000 psi. The new models — the first NLB convertible quintuplex pumps — have many features and parts in common with the popular NLB 225 Series. This simplifies operation, maintenance, and inventory for water jetters who use NLB 225 units.

Two diesel-powered models are available, each with a low-wear quintuplex pump and a convenient swing-out manifold that makes conversion easy. Model 405 (400 hp) can be converted to run at 8,000 psi, 10,000 psi, 12,000 psi, 15,000 psi, 20,000 psi, and 24,000 psi. Flows range from 25 gpm to 74 gpm. Model 365 (365 hp) can run at 8,000 psi, 10,000 psi, 12,000 psi, 15,000 psi, 20,000 psi, and 24,000 psi. Flows range from 22 gpm to 64 gpm.

Want more information? Click below.

NLB Corp.

Tough tight-bend hose for material handling apps

Parker Hannifin has released its 692 hose line, designed specifically for material handling and over-the-sheave applications. The design and construction of the 692 hose allows for a tighter bend radius compared to other hoses on the market, which saves space in the mast and increases visibility for the operator.

To improve visibility for the lift truck operator, components must be moved or reduced in size. Parker's new 692 hose addresses both concerns. Rated to the tightest bend radius in the industry, the 692 hose enables smaller pulleys to be used in the mast area, freeing up space. With a smaller outside diameter than other hoses, more area is gained in the mast area which improves visibility.

Want more information? Click below.

Parker Hannifin

Most Requested Mechanical Products

1. Mounting shaft collar secures components, adjusts easily

A mounting shaft collar for securing gears, pulleys, sprockets, and related components onto a shaft, while permitting easy adjustability, has been introduced by Stafford Manufacturing. Stafford Accu-Mount Collars have a split design that features one solid, square, and flat side (with four mounting holes for attaching components) and a second side that clamps securely to a shaft and is easy to reposition. Providing a centering hub and rigid mounting method for a variety of drive components, these collars have a smooth bore to protect expensive shafts.

Designed to prevent slippage and vibration while allowing for easy repositioning, Stafford Accu-Mount Collars are machined from steel. They are available in 11 sizes.

Want more information? Click below.

Stafford Manufacturing

2. Tabletop CNC router offers a big product in a small package

A new size CNC router has been added to Techno’s successful LC Series product offering. The new size machine is the Model 3024 LC Series Tabletop CNC Router. This NEW LC Model has a work envelope of 30 in. x 24 in. x 5 in. and is equipped with Techno's closed-loop servo motor drives.

In addition, it comes complete with Techno's Window-based Gcode Interface that is upgradable FREE for the life of the machine. It can be equipped with a variety of spindles and accessories, including automatic tool changer, laser scanner, 4th-axis rotary table, and a variety of clamps.

Want more information? Click below.

Techno, Inc.

3. World’s smallest precision ball bearings

SPB-USA, located in Sarasota, FL, has available the world’s smallest ball bearings manufactured in Japan by Sapporo Precision Inc. under the EZO-SPB brand name.

Each bearing has an inside shaft diameter of just .06 mm or .0236 in. and outside diameter of just 2.5 mm and a width of 1 mm. Each ball, and there are five in each race, is smaller than those found in a ballpoint pen, and each is precision ground to an exacting specification to ensure long life at operating speeds of between 142,000 rpm and 160,000 rpm.

Want more information? Click below.

SPB-USA

4. Duct stays in place, once bent

Flexaust Pliaduct is a 100% rigid, self-supporting PVC duct with a ribbon-lock construction that lets users expand the diameter up to 25% by twisting it, using both hands, to fit nozzles, funnels, or fittings. Ideal for spot cooling applications, this wireless, flame-retardant duct may be reshaped and spliced together without tools and stays in place once bent.

Want more information? Click below.

Flexaust

5. Shaft sealing solution optimizes lubricant retention

SKF low-friction Waveseal shaft-sealing solutions feature a specially molded lip to form a sinusoidal or wave pattern around the shaft surface. This unique pattern enables lubricant to be pumped back to the bearing for optimized lubricant retention while pushing dirt away from the lip/shaft surface (regardless of which way the shaft is turning) to protect against contamination.

The specially designed lip additionally generates 25% to 35% less heat at the contact point (minimizing premature seal failure due to heat checking, blistering, hardening, or lubricant breakdown); generates 20% less friction torque or drag; curbs shaft wear; and provides greater lip lubrication compared with standard lip versions.

Want more information? Click below.

SKF

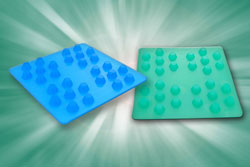

6. Gel pad vibration isolators for damping performance

A new series of silicone gel pad vibration isolators from Advanced Antivibration Components features superior damping performance. V10Z61MSN Series isolators are designed for light to medium loads from 0.5 kgf to 2 kgf (1.1 lb to 4.4 lb) up to 15 kgf to 50 kgf (33.1 lb/leg to 110.2 lb/leg) per mount.

Their highest damping effect arises when the gel is compressed 10% to 30%. An important feature of these metric mounts is their ability to operate effectively over a very wide temperature range from -40°F to 392°F. They offer excellent chemical resistance and are low in compression set. Performance remains the same even after repeated use. They stay stable with low resonance magnification and have minimal horizontal deflection.

Want more information? Click below.

AAC

7. Updated website from Precision Screw & Bolt

This new website features a more user-friendly design and updated information. A few new features include request forms for quotes and the ability to place fastener orders online. Other areas of the website include information on complete product and engineering data capabilities, literature requests, further resources, as well as a contact form for any additional information or questions. A section titled “Got a Fastener Problem?” allows users to submit requests for help in finding a solution for their specific fastener needs.

Want more information? Click below.

Precision Screw & Bolt

8. Get a handle on high-volume epoxy sealing

Multi-Seals offers an innovative alternative to liquid epoxy for high-volume, high-quality epoxy sealing applications. Uni-form epoxy preforms are one-part epoxy resins that are solid at room temperature. When heated, Uni-forms melt and cure, forming a consistent seal that protects components from dust, moisture, oil, flux, solvents, conformal coatings, and other contaminants.

Close tolerances on preform configurations, consistent pre-mixed ratios of resin to catalyst, and consistent viscosity from beginning to end of batch ensure uniform, high-quality results. Preforms can be dispensed as rapidly as 200 to 600 parts per minute with little or no operator training, and extensive operator experience is not required to produce uniform results. Preforms also eliminate pot-life concerns and costly cleanup procedures. Uni-forms are available in a wide range of shapes, sizes, and materials to accommodate diverse applications.

Want more information? Click below.

Multi-Seals

9. Lifting rings, locking pins, and spring plungers meet DoD requirements

Jergens, Inc. has announced that three of its major product lines can be compliant with Defense Federal Acquisition Regulation Supplement (DFARS) 252.225-7014 Alternate 1 Preference for Domestic Specialty Metals. The requirements stipulate that certain specialty metals used in parts supplied to the Department of Defense by a U.S. company be melted in the U.S. or certain qualifying countries.

“We are pleased to offer domestically sourced specialty metal products to the DoD and other customers,” says Jack Schron Jr., Jergens’ president. “Although any item Jergens sells has the potential to be purchased as a DFARS item, we expect the most commonly requested items to be our Kwik-Lok Locking Pins, lifting rings, and spring plungers.”

Want more information? Click below.

Jergens

10. Professional, high-definition 3D printer

3D Systems Corporation launched the ProJet HD3000 3-D Production System, a new, professional, high-definition 3D Printer, at SolidWorks World 2008 in San Diego, CA.

The new 3D Production System is a next-generation 3D printer based on 3D Systems’ patented and proprietary Multi-Jet Modeling (MJM) technology. This high-throughput 3D printer provides best-in-class part quality and accuracy. It also provides the choice of both high-definition and ultra-high-definition build modes in a single system.

Want more information? Click below.

3D Systems

Stainless steel spline shaft for light to moderate load apps

Kerk Motion Products has expanded its Kerk Spline Shaft Series with the introduction of its new stainless steel option. The Spline Shaft Series can now be manufactured in 304 stainless steel on its SS2 through SS8 Series spline shafts, which range from 1/8-in. to 1/2-in. diameters, and include the full range of bushing options for these sizes.

The entire spline shaft series includes Kerk’s proprietary, low-friction Kerkote TFE coating, including all the standard configurations offered in the series. Stainless steel offers the maximum corrosion resistance and is the most versatile configuration. The Spline Shaft Series has been designed for light to moderate load applications, where low cost, low friction, and long life are critical design considerations. This includes any application that requires a rotary drive with adjustable linear position or a linear guide with high torsional stability.

Want more information? Click below.

Kerk Motion Products

Cable clamps design to install without damage and tangles

Heyco Products is now offering a new line of Push Lock Cable Clamps and Snap Lock Cable Clamps for clamping cable/wire/hose bundles securely in place.

Available in black or natural, Push Lock Cable Clamps can accommodate 0.187-in. (4.8-mm) mounting-hole diameters, 0.125-in. (3.2-mm) panel thicknesses, and feature push-in arrows for quick and easy installation with no additional hardware. Snap Lock Cable Clamps are also available in black or natural, fit 0.190-in. (4.8-mm) mounting-hole diameters, and lock securely but can be removed and reused with a #10-size screw. The Snap Lock Cable Clamps can be preassembled on wire/cable/hose for ease of installation and can be installed without forcing the clamp open to avoid damage and tangle to the wire/cable/hose bundles.

Want more information? Click below.

Heyco Products

Bearings deliver high performance in harsh environs

Danaher Motion introduces Thomson Stainless Steel MultiTrac Ball Bushing bearings. Constructed of 440 stainless steel components to resist rust and corrosion, these bearings are built to thrive in harsh environments with temperatures up to 180ºF (82ºC). Machine builders will benefit from extended service intervals and longer bearing life, increased machine reliability, and reduced service and support costs. They feature a patented multiple track design that delivers up to twice the load carrying capacity, or eight times the operating life, of conventional linear bearings.

When combined with Thomson stainless steel 60 Case shafting, the shaft life is also extended when compared to conventional shafting. Most sizes are available with same or next day delivery.Thomson Stainless Steel MultiTrac Ball Bushing bearings deliver steady-state travel speeds up to 10 ft/s (3 m/s) and accelerations to 450 ft/s2 (150 m/s2), without the use of derating factors that are typically necessary with competitive products.

Want more information? Click below.

Danaher Motion

Platinum-cured silicone hose adds safety to hose handling

Platinum Cured Silicone Hoses from Parker PAGE offer a seamless, flexible convoluted or smoothbore hose with an additional extruded silicone layer over the hose. The silicone layer protects the braided hose from contaminants and ensures safer operating handling due to contained braid fray and insulation from heat. Also, the Platinum Cured Silicone Hoses are autoclavable and the seamless Silicone allows for easy cleaning.

Platinum Cured Silicone Hoses have an operating temperature up to 450ºF/232ºC and are available with a smoothbore or convoluted core in sizes ranging from 1/4 in. I.D. up to 2 in. I.D. They also use a single-piece crimp collar, allowing for full working pressure potential and silicone weather seal.

Want more information? Click below.

Parker Hannifin

© Nelson Publishing, Inc. All Rights Reserved